We will professionally modernise your control room with innovative details

Do you want to modernise your control room? Your current control room has some weak spots that need to be fixed? You want to reduce costs and increase efficiency at the same time? In addition, you want to take into account investments that have already been made in your existing control room?

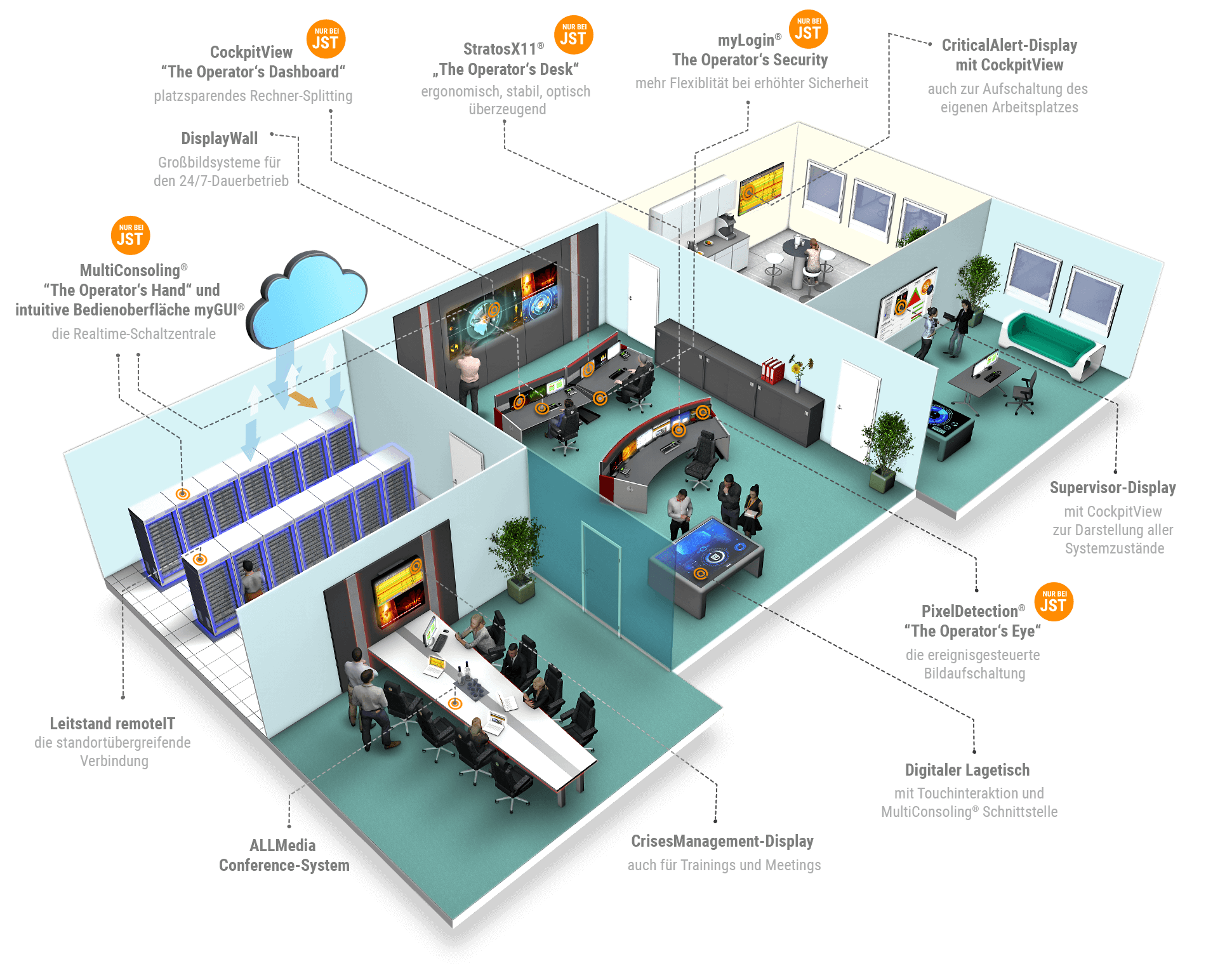

JST offers you well thought-out solutions to modernise your control room that are designed to meet your individual needs. Whether it is scalable monitor walls or ergonomic control room furniture – JST does not just make your control room look better by modernising it. We also provide you with optimal equipment for the future, make your company more efficient and your employees happier.

-

Individual planning in line with your control room.

-

Protect and continue to develop the investments in your control room.

-

Modernised control rooms reduce heat and noise.

-

Ergonomic control room furniture provides more comfort.

-

Perfect overview and efficient operation after modernisation.

Chosen by leading companies and institutions

Practical examples: Control room modernisation

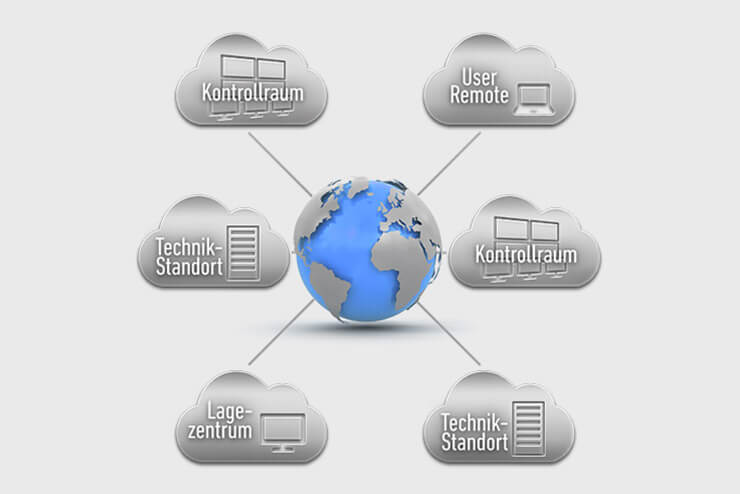

JST has already modernised numerous industrial control rooms. Even while maintaining 24/7 continuous operation. We skilfully demonstrate our strengths when it comes to industrial safety requirements, decoupled network structures and the highest demands on the operating concept! You are sure to find an example project among our reference reports on modernised control rooms that meets virtually all of your requirements for a new control room.

We will be happy to put you in touch with the appropriate contact person.

Most modern measuring station for PCK refinery

PCK Raffinerie GmbH in Schwedt/Oder is one of the top companies in Brandenburg and the most important company in the Uckermark. Around 12 million tonnes of crude oil are processed into petroleum and petrochemical products in Schwedt every year. The main products are diesel, petrol, kerosene, liquefied petroleum gas, heating oils and bitumen. PCK was one of the first refineries in Germany to use biofuels and is itself a major producer of high-quality biofuel components.

Chief Divisional Engineer for Processing (PCK) / Divisional Engineer for Maintenance Service and Project Coordinator (PCK) / Managing Director (JST)

Modernised control room as the centerpiece of the MVA - waste recovery plant

All operating and emissions data are collected by them, they check that the limit values are never exceeded, thus guaranteeing the highest safety standards: The operators in the new control room of Müllverwertungsanlage Bonn GmbH (MVA), a subsidiary of Stadtwerke Bonn, are responsible for monitoring all data and functions at the core of the plant. This important task is supported by products from Jungmann Systemtechnik – JST.

Plant Manager of MVA Bonn

Production control room with completely new equipment

The monitoring of around 2,000 computer systems is the focus of the employees at Audi’s so-called “MMS” control room in Ingolstadt. MMS – that stands for Manufacturing Management System. This involves continuous testing of all the steps required to produce the various models. The new control room was equipped by the control room specialists from Jungmann Systemtechnik.

Head of Maintenance Processes and Systems Engineering / Control Center Coordination / Project Manager

Was möchten Sie als Nächstes tun?

FAQ

How can we integrate additional systems into our control room that has grown over the years?

Before we start modernising your control room, we create a completely unique design concept. We start by analysing the potential for improvement and making optimal use of all possibilities and resources. JST also optimises teamwork and creates a better overview through proactive and intelligent monitor walls. The JST display walls are ideal for this. Computers and cameras can be automatically switched on and operated in real time without the need for an operator. This brings the entire team up to the same level of knowledge at all times and gives them a perfect overview of the most important alarms.

How can a modernised control room improve the conditions for our employees?

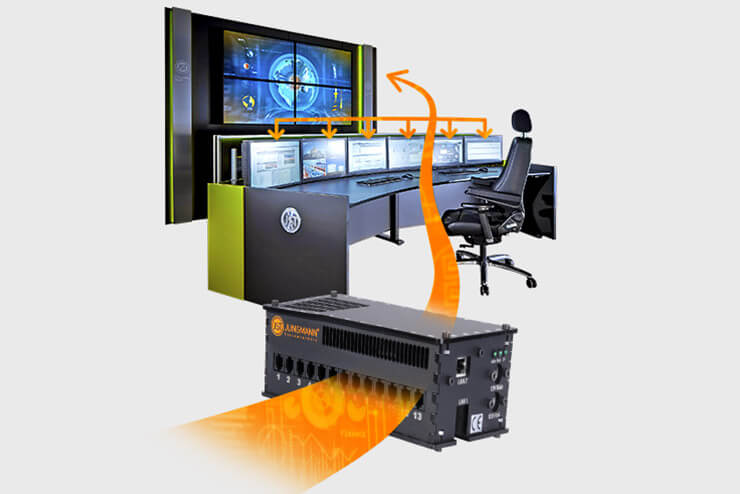

Working conditions in a control room that has grown over time have often stopped being optimal. Fast action becomes almost impossible. Loud noises and excessive heat create difficult conditions, where fast and focused action is essential. In this case, we create the perfect working environment by cleverly relocating computers. We improve both the indoor climate and the acoustics of the room by installing all workstation computers in a separate technical room. Our KVM Extender is a solution that vastly reduces noise levels in control rooms and control centers and prevents unnecessary heat emission. In a separate technical room, with protected access, an air conditioning system can be installed to counteract the heat generation in the modernised control room.

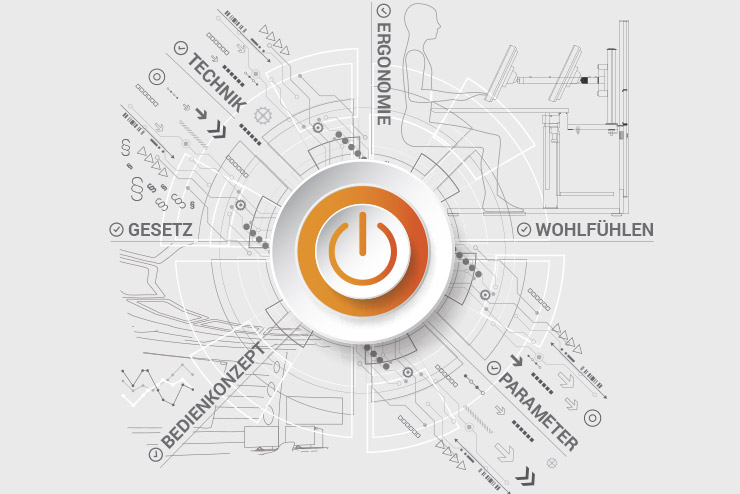

Do you take ergonomic aspects into consideration when modernising new workstations in the control room?

YES! Improving the ergonomic working conditions of your employees is especially important to us. Our free online analysis allows your employees to evaluate the current situation. The survey is anonymous. However, we take the results into account in our planning. For this, we assess the current ergonomic conditions, while taking the latest guidelines of the Federal Institute for Occupational Safety and Health concerning workstations with visual display units in control rooms into consideration. We also take the operators’ subjective impressions very seriously. We take all these factors into account when modernising control rooms.

We are happy to answer any questions you have regarding the modernisation of control rooms

0800-777 8 666You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information