Rail operations center for electronic interlocking

In rail transport, around 40,000 trains run on German rails every day.

This bustling activity is planned, controlled and monitored by the traffic controller in the electronic rail interlocking control centers, the control center for the railway interlocking.

This is how rail traffic can run safely.

Preferably trouble-free.

A total of 3,000 interlocking control centers of all types are entrusted with responsible tasks.

Today, modern electronic interlocking control centers (ESTW) have significantly improved operations management for the train dispatcher.

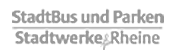

JST offers state-of-the-art technology that is precisely adapted to the planning and optimization of the interlocking’s control center.

With our specially developed JST Profi-Tools we give the dispatcher the best support in 24/7 operation.

-

One for all: Architecture, technology, light, acoustics, climate.0

-

Ergonomically right at the front: control room furniture from Germany

-

Everything in view: monitor walls for the 24/7 operation

-

Comprehensive: baua study, professional association, VBG, escape routes

-

Optimal: pleasant working atmosphere, suitable design

Chosen by leading companies and institutions

Practical examples: Electronic interlocking control centers railway

Jungmann Systemtechnik with its team of experts is the ideal partner for the planning, modernization and implementation of control centers and electronic interlocking control centers (ETSW) for railways.

Already in the early planning phase, JST considers all decisive components such as ergonomics, viewing angle, lighting, furniture, technology and software, infrastructure and the adaptation of existing systems and networks.

In the electronic interlocking control centers, successful establishment ultimately also includes successful human communication.

In our reference projects we show you how this composition can look like after project completion.

We will be happy to put you in touch with the respective contact person.

New control center for traffic monitoring with monitor wall and flexible control

Rush hour traffic in the city.

The streets are full and commuters gather at the local transport stops.

If a bus breaks down now, it’s gonna be tight.

In the event of breakdowns or delays, everything depends on the control center in the university town of Göttingen.

There, ideal technical conditions for traffic monitoring have now been created in favor of reaction time.

With products from JST, the employees of the Göttinger Verkehrsbetriebe GmbH keep the overview.

Operations manager / traffic master / administrator

New traffic control center is the heart of the subway

“We have proven that Berlin construction projects can be completed on time and without increasing costs,” says Antje Michalak, responsible for the “Control Centers 2014+” project of Berliner Verkehrsbetriebe, which includes the new operations control center for the subway (BLU).

This new building project with a total budget of 8.9 million euros was also supported by Jungmann Systemtechnik.

170 employees control the train traffic around the clock from the heart of the Lichtenberg underground.

Subproject manager IT technology / overall project manager / subnetwork manager

New control room for more safety in operating processes

Whether simulated extreme conditions or realistic prerequisites – hardware and software of railway systems from Siemens are thoroughly inspected in the Wegberg-Wildenrath Test and Validation Center.

A track system over 30 kilometers long is available there.

Static and dynamic tests are performed on vehicles and systems 365 days a year.

A task that requires a perfectly equipped control room for monitoring.

With the assistance of the experts from Jungmann Systemtechnik a control room could be realized, which meets all requirements.

Project manager

Was möchten Sie als Nächstes tun?

FAQ

What are the advantages of setting up a modern control center for the electronic interlocking (ESTW) at the railway?

Railway companies that value high quality standards and high performance are now setting up electronic interlocking control centers.

Where operating levers and buttons used to make quick reactions difficult, today the mouse and roller ball facilitate the quick actions des of the dispatcher. State-of-the-art monitor walls, clevere professional tools and ergonomic control room furniture make work in the railway’s electronic interlocking simple, fast and safe.

Modern operation centers for interlocking control centers not only provide a high quality standard but also an enormous performance.

This is why modern electronic interlocking control centers play an increasingly important role for railways.

Push buttons interlocking control centers

- Less flexibility in case of malfunctions, as there are fewer options

- Only 6-7 km range, requires more interlocking control centers

- Outdated relay technology requires more space

- Analogue operation of the pushbuttons stops and loads

- Slow reaction times, technical processes and actions take unnecessarily long

Electronics interlocking control centers ESTW

- High flexibility in case of failure, as more options

- Less interlocking control centers necessary due to long range

- Modern technology requires much less space

- Ergonomic and less tiring operation of the systems

- Fast reaction times and automated processes in case of emergency

What technology is used in an electronic interlocking control center for the railway when setting up a control center?

The task of the interlocking control centers for rail is actually always the same: Here, points and signals are set so that a train can run safely and punctually on the planned route according to the timetable.

For this it is necessary that the line is secured by signals and that it is avoided that further trains cross or run over switches on the same track.

Fortunately, turnouts no longer have to be operated by hand directly on the track.

Nevertheless, there are still outdated interlocking control center technologies of various manufacturers and different designs.

This leads to a considerable number of variants of the control and security technology used.

Dispatchers therefore have to be instructed for several weeks before being deployed in a new interlocking control center.

The current trend is to set up electronic interlocking control centers.

JST is an experienced expert in the planning and implementation of electronic interlocking control centers for the railway.

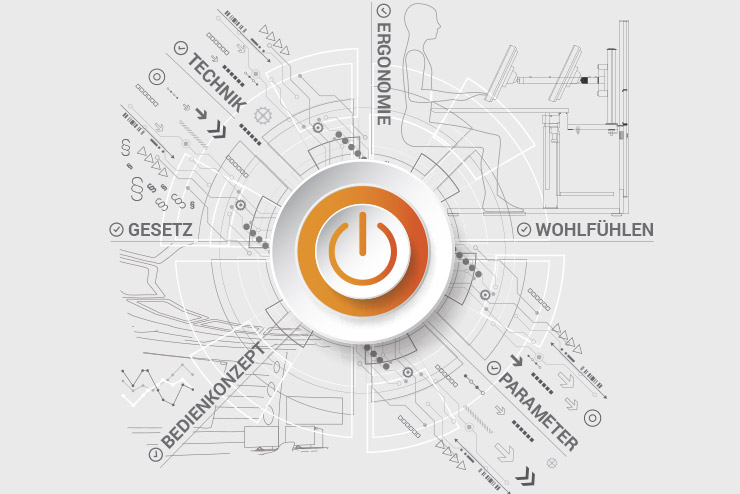

The basis of a modern railway operations control center is always the optimal display of the systems on the corresponding monitor walls.

Our components for an advanced interlocking control center for the railway:

- MultiConsoling® and myGUI®: Achieve maximum flexibility and simplify the operation of your systems.

- CockpitView: The operator’s personal dashboard – shows everything at a single glance.

- PixelDetection®: A fast-paced tool.

It reduces the reaction time to a minimum. - myLogin®: Turns logging in at any workstation into a safe and secure child’s play.

- Control room furniture: Innovative ergonomic concepts for fatigue-free and concentrated work.

We will be happy to answer your questions on the subject of electronic railway interlocking

0800-777 8 666You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information