Photo 1 | JST control center: The new control center of MVL GmbH not only convinces with its successful optical design - thanks to the modern video wall and the flexible control by JST MultiConsoling®, technically perfect conditions could also be created to be able to react faster, more flexibly and more efficiently to market and customer requirements.

Photo 2 | Entrance to the new control center - behind the door is a technically and ergonomically excellently coordinated concept.

Photo 3 | View of the MVL premises. The company secures a quarter of Germany's crude oil imports from Schwedt in the east of Uckermark.

Photo 4 | Mineralölverbundleitung GmbH supplies refineries in Schwedt, Brandenburg, and Leuna, Saxony-Anhalt, with around 21 million tons of crude oil per year via ten tanks on the company premises with a total capacity of 300,000 cubic metres and a pipeline network more than 750 kilometres long.

Photo 5 | A control center with two operators per shift monitors all processes in the company's own tank farm and pipeline network around the clock and controls a valve station 300 kilometres away.

Photo 6 | A look inside the old MVL control center: Over a period of 20 years, a colourful hotchpotch of monitors has accumulated here that was almost impossible for operators to keep track of.

Photo 7 | JST control center concept: Thanks to the video wall and flexible control by JST MultiConsoling®, the number of workstation monitors and mouse/keyboard units has been reduced to a minimum. Positive effect: more clarity and shorter reaction times.

Photo 8 | JST CommandDesk: The control center desks offer numerous ergonomic advantages. In addition to generous legroom and a particularly deep table top with lowered monitor installation surface, these include in particular the motor-driven height adjustment, ...

Photo 9 | JST operator console: ...which, for example, allows switching between sitting and standing. Each operator can thus adapt "his" Stratos X11® CommandDesk to his specific needs.

Photo 10 | JST control center desks: No matter whether front or rear: the Stratos X11® OperatorDesk gives a clean and tidy impression at all times, without visible technology or cables. …

Photo 11 | ... Behind the revision flaps are generously proportioned, illuminated supply rooms that offer sufficient space for technology and large quantities of cables, thus creating a perfect picture in the control center.

Photo 12 | JST Video Wall: In addition to the workstation monitors, the proactive large display wall with eight LC displays is also used intensively to call up and operate the process control system flexibly. In the case of common tasks, the various features are examined by the operators there and problems or actions are discussed intensively.

Photo 13 | JST monitor wall: The JST DisplaySuit with brushed aluminium surfaces serves as the basis for the tried and tested QuickOut mounting system, in which individual displays can be easily pushed forward by applying light pressure to the outer edges. A perfect opportunity for optimum service accessibility without interruption of operation.

Photo 14 | JST MultiConsoling®: With the graphical MultiConsoling user interface myGUI®, all consoles of the workstations and the large display wall are displayed as "control room picture". JST MultiConsoling®: With the graphical MultiConsoling user interface myGUI®, all consoles of the workstations and the large display wall are displayed as "control room picture".

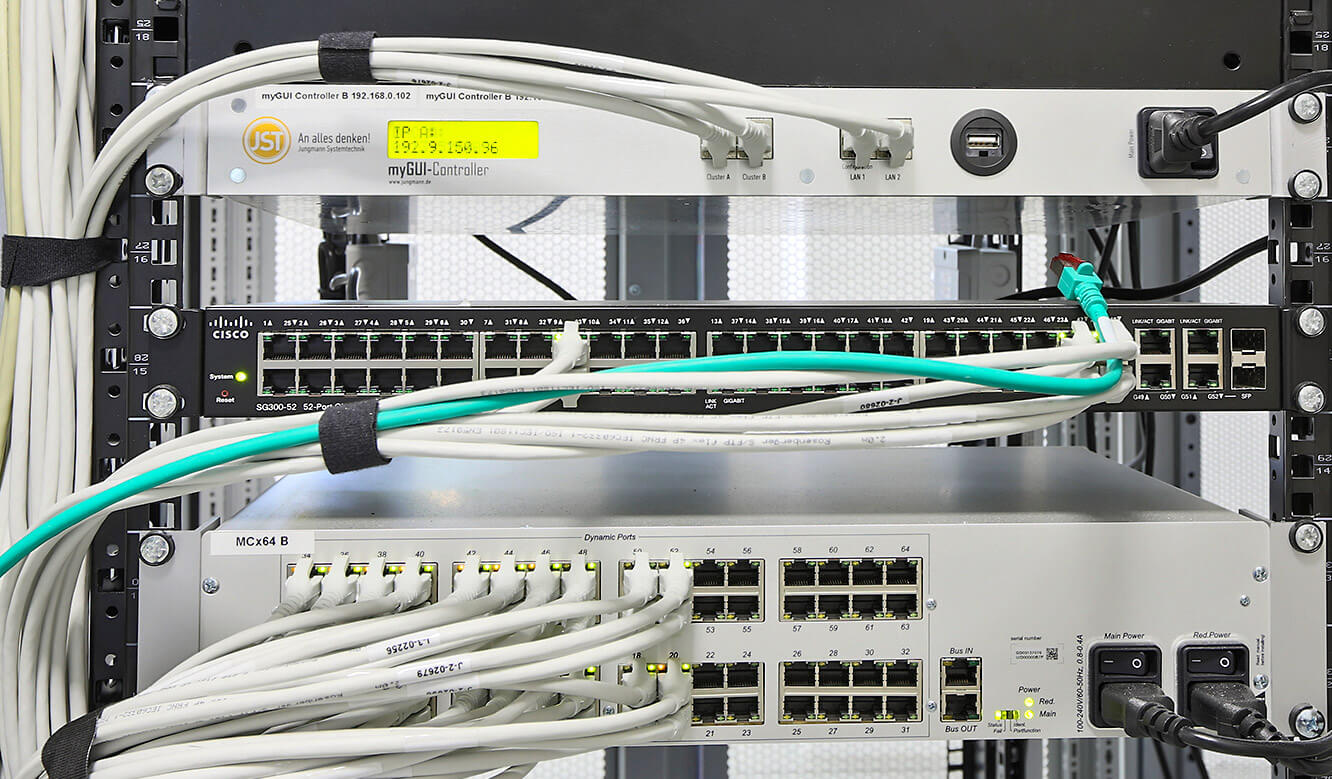

Photo 15 | JST technology: Sophisticated hardware; from top to bottom: myGUI® Controller, CrossConnector and the MultiCenter, the heart of JST MultiConsoling®, a control technology that enables flexible connection of all desired applications to the video wall and workstation monitors.

Process optimisation and maximum reliability with modern control center

Pascal Havy, Managing Director of Mineralölverbundleitung GmbH (MVL) in Schwedt, describes the group’s new state-of-the-art control center as the “figurehead for modernisation” of the entire company. The extensive project was realised with the support of the JST control room specialists. The advantages are obvious: maximum system stability, reduced reaction times and the ideal conditions for lean management to be able to react faster, more flexibly and efficiently to market and customer requirements.

It is responsible for supplying two refineries in Brandenburg and Saxony-Anhalt. For this MVL Schwedt coordinates transport, transhipment and storage of crude oil via pipelines that reach from Russia via Poland to Schwedt in Brandenburg and from there to the local PCK Raffinerie GmbH and the Leuna Chemical Park. MVL thus secures one quarter of German crude oil imports. Security of supply is at the top of the list of requirements.

20-year-old control center with serious deficits

This is where the control center comes into play. The linchpin when it comes to performance guarantees. “With our 20-year-old center, this could hardly be guaranteed,” says Pascal Havy. The MVL Managing Director names the decisive weaknesses of the old control center: poor positioning, acoustic and climate problems, poor lighting and glare effects, and outdated ergonomic equipment. But also with regard to the demographic development, an increasing lack of skilled workers in the structurally weak region and possible compensation through improved technical facilities, the outdated control center was no longer a solution.

The control center before and after modernisation

Innovative control center concepts from JST have convinced

At his business partner PCK, who together with Jungmann Systemtechnik implemented the most modern refinery control center in Europe, Pascal Havy was inspired by the possibilities and convincing innovations thanks to a technically and ergonomically innovative control center concept. The JST control center at the “windpunx” branch office in Potsdam also scored points with the MVL managers. “We have sounded out the market thoroughly and are simply convinced that JST is the best partner for us,” says MVL’s Managing Director, “Consulting, technology and quality are just right. At JST you deal with professionals from A to Z”.

Usability as "most important parameter”

But how do you manage to persuade a well-rehearsed control room team to deal with completely new technology ? How can acceptance be created for the idea of reducing the number of workplace monitors from nine or even ten to just three displays per workplace? The solution lies in the word usability. Pascal Havy: “This is the most important parameter for me.” This includes modern software tools that enable intuitive operation. A proactive video wall that displays all important events event-driven. And an ergonomic concept which, thanks to modern furniture with height-adjustable control center desks, puts health aspects into focus.

Operator team now works under optimal conditions

Optimum air conditioning, noise minimisation through outsourced technology and the spatial positioning of the control center are also among the clear plus points of the project. For the MVL Managing Director there is no question: “The operator team is now working under optimal conditions, the colleagues have got used to the new technology step by step. The monitor wall also promotes cooperation; problems can be discussed together”.

"Colleagues are proud of their new control center"

Pascal Havy concludes: “The project was really fun. With the JST products, the appropriate infrastructure is now available for all our tasks – also for a planned optimisation in the shift system. And the colleagues are proud of their new control center – you can see that especially when visitors are visiting”.

Project video - New control center at MVL in Schwedt

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationPress review

Unsere Referenzen heute (Auswahl)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)