Photo 1 | JST control room: The control room of the Nord-West Kavernengesellschaft mbH (NWKG), which has a fully redundant technical design, secures oil storage in salt caverns at the gates of the coastal city of Wilhelmshaven in Lower Saxony. The control room professionals from JST are convincing here with an overall concept that takes into account both technical and ergonomic aspects as well as the demand for maximum availability.

Photo 2 | JST design: Thanks to realistic 3D planning sketches, those responsible at NWKG were able to get an accurate picture of the new control room in advance.

Photo 3 | JST control room: The conversion of the previous 3D sketch into reality. Project manager Lars Janßen: "The technical support in spatial planning helped us a lot."

Photo 4 | JST photo shoot: The look "behind the scenes" - positioning for a group photo during the photo shoot in the new control room.

Photo 5 | Soon a control room: still a construction site - the control room is to be built in this room in the new NWKG building...

Photo 6 | ...and after completion: High-quality ergonomic furniture and HCL (Human Centric Lighting), combined with colored AlarmLight make the control room an attractive working environment.

Photo 7 | JST control room before: Already a bit outdated - in NWKG's old control room, too, a large screen wall served to support process monitoring. Since the current control room is housed in a new building, the previous installation now takes on a new role: it is available as a backup control station.

Photo 8 | JST control room after: Larger displays with high resolution and ultra-slim frames optimize the representations from the plant operation.

Photo 9 | JST control room desk: Whether standing or sitting - workstations of the Stratos X11® perform to the highest ergonomic standards. Electric height adjustment, lowered monitor assembly levels and a generously dimensioned foot garage are just some of the features that make the Stratos a control room bestseller.

Photo 10 | JST operator desk: Flaps on the back ensure that the Stratos control room desks always present an impeccable visual image in the control room. Cables, power supply units or similar are not to be found here.

Photo 11 | JST control center desk: Stratos series desks feature spacious, illuminated supply spaces, allowing for properly installed technology, with no visible cables.

Photo 12 | JST AlarmLight: Depending on the individual setting, the AlarmLight can be used as a homely lighting option in the "idle state".

Photo 13 | JST AlarmLight: Consoles, sideboards, ceiling sail and the cover of the large-screen technology - all furniture components at NWKG are equipped with the versatile AlarmLight. In case of malfunctions, alarms are indicated by red flashing.

Photo 14 | JST ceiling cloud: The OPAL acoustic ceiling sail was developed on the basis of occupational health requirements for shift operations in control rooms. On the one hand, it effectively reduces room noise and, at the same time, serves as a light source through HCL - Human Centric Lighting, which improves concentration and performance by changing the color temperature.

Photo 15 | JST workstation monitors: The screens at the operator workstations are equipped with individually adjustable 3D hinged arms. This allows a perfect viewing angle to be set.

Photo 16 | JST control room furniture: Sideboards - equipped with the AlarmLight - were individually manufactured in the JST furniture manufactory in coordination with the needs of the employees.

Photo 17 | JST furniture: Acoustically effective material - the surfaces of the control room furniture have sound-absorbing characteristics.

Photo 18 | JST furniture: Behind the sliding doors of the sideboards are technical tools that are used in everyday control room operations. The "inner life" of the furniture pieces was specially adapted to the specifications of the workforce.

Photo 19 | JST furniture: space-saving and practical - custom products include solid, pull-out shelves that can support heavy loads such as a printer.

Photo 20 | JST furniture solutions: Custom-made products, such as cabinets with storage compartments for employees that are adapted to the exact centimeter, are among the characteristic features of JST furniture manufactory.

Photo 21 | JST large-screen technology: The DisplayWalls from JST are specially designed for 24/7 continuous operation in control rooms. Operating tasks can be performed simultaneously or alternately and in real time on the DisplayWall. This makes them a real extension of the workstation desktop.

Photo 22 | JST large-screen displays: Perfect illumination thanks to energy-saving LED backlighting and high pixel resolution - with their ultra-slim frames, the latest generation displays are ideal for BigPicture presentations across multiple screens.

Photo 23 | JST control center equipment: Convenient operating elements integrated directly into the tabletop of the Stratos console. Front left: With the PowerPort Data-Box, all desired connections are directly available at the workstation. Top right: The individual switches of the CommandButton Box were assigned preset functions in the NWKG control room. This allows each employee to call up their individual default settings with a single push of a button when changing shifts.

Photo 24 | JST control room: Safety has top priority in the process monitoring of the cavern plant. With the physical switches, an immediate stop of individual plant elements can be warranted in a hazardous situation - without prior access to operating functions of the control system. Project manager Lars Janßen: "In this way, the plant is shut down in a controlled manner in the event of an incident."

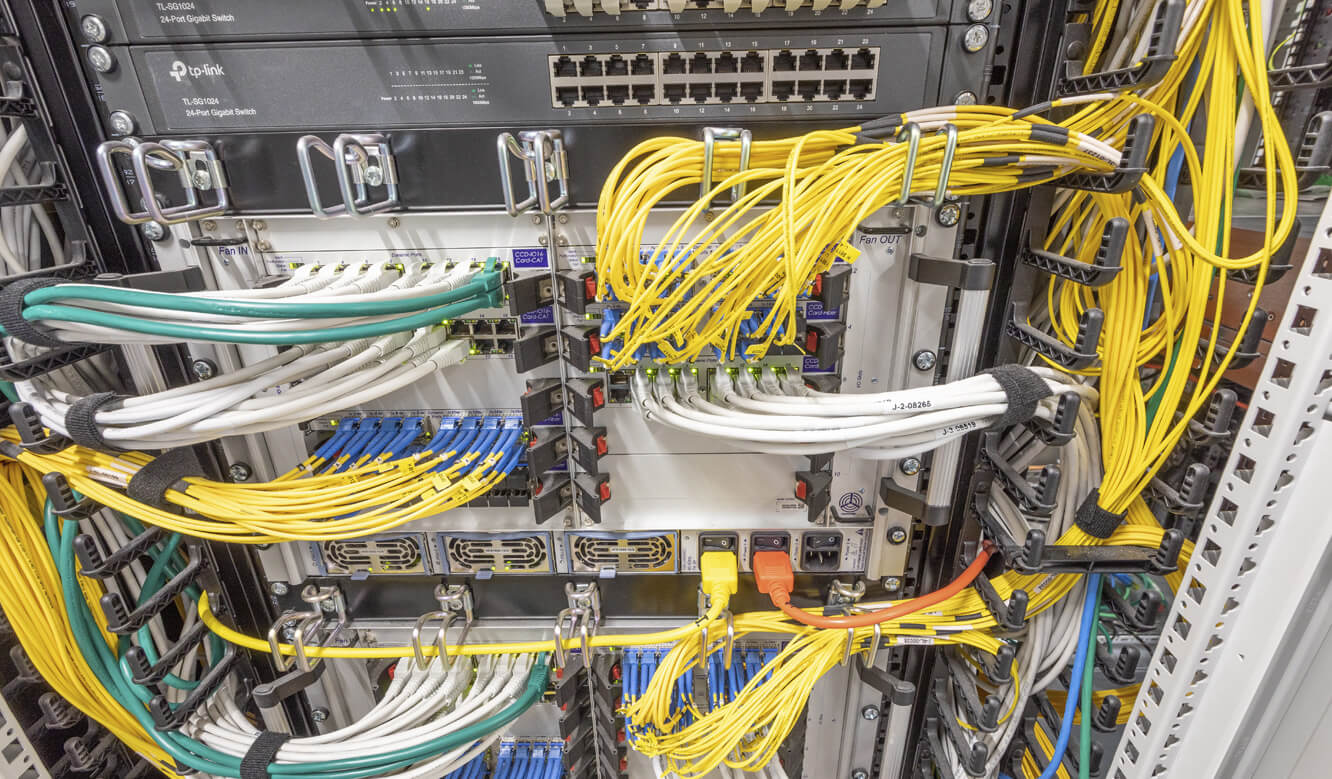

Photo 25 | JST MultiConsoling®: Modular and highly available - the MultiCenter (heart of control room operation via MultiConsoling®) with fiber optics and copper connection ports as well as redundant power supply.

Photo 26 | JST VM concept: With the GrabberVM® component - here in a fully redundant version - virtual machines can be conveniently integrated into the system architecture of the control room.

High-availability control room supervises processes of oil storage in caverns

Nord-West Kavernengesellschaft mbH (NWKG) is one of the major cavern operators in Europe. The company’s largest cavern site is located near the port city of Wilhelmshaven in Lower Saxony. The administrative headquarters and a high-availability control room, whose employees do their part to ensure Germany’s strategic oil reserve, are also stationed there. For the technical and ergonomic equipment of this control room, NWKG has been relying on the know-how of the JST – Jungmann Systemtechnik® control room specialists for more than a decade.

Hundreds of meters below the earth’s surface (underground), up to 11.5 million cubic meters of crude oil can be stored in deep-lying salt deposits in artificially created caverns on the periphery of Wilhelmshaven. This is the way these huge underground reservoirs work: Oil is lighter than water. When oil is pumped into the salt cavern, it displaces the water that fills the cavern. If, on the other hand, water is pumped in, the oil floats to the top and is thus forced out of the cavern.

After almost twelve years, cooperation with JST again

In order to permanently monitor the processes of oil storage and retrieval and also its emplacement, the operators of the new control room have a 24/7 view not only of camera images, but also of pressure sensors, pumps and drives. “We run the cavern operation with this highly available control room,” summarizes Lars Janßen, head of electrical engineering at NWKG. The engineer worked with the Jungmann team more than a decade ago to implement a control room. Today, almost twelve years later, he has used the new construction of the NWKG administration building to benefit again from the know-how of the JST experts when planning a new control room.

Operators consciously involved in the decision

“Even the workshop in the control room simulator was a perfect introduction,” reports Lars Janßen. “We were able to see and touch everything on site, operate the technology and directly imagine the benefits the new installation will bring. It helped a lot that the operators accompanied us on this visit and that they were deliberately included in the decision-making process.”

Interactive experience in the new control room: Zoom, rotate, nighttime view and change of perspective – here you can experience control room concepts in interactive 360 degree visualisations! How does the new control room look? How can the operator consoles be optimally positioned? How big should the monitor wall be? With professional 3D studies and virtual tours – here at NWKG in Wilhelmshaven – these and many other questions can be answered at an early stage of the project. Light influences, colours, spatial conditions – there are almost no limits to the design possibilities. Go on a three-dimensional journey of discovery now!

In case of critical malfunctions, red flashing light pulses

In fact, NWKG employees were spontaneously enthusiastic about the possibilities realized with JST components in the new control room: ergonomic furniture with the Stratos control room console, the OPAL X11® acoustic ceiling sail, and extensive furnishings with customized cabinet and sideboard solutions – all equipped with the AlarmLight, which generates attention with red-flashing light pulses in the event of critical fault messages. In addition, a large screen wall whose high-resolution displays are perfect for cross-screen BigPicture presentations, for example, thanks to ultra-narrow frames.

MultiConsoling® performs all requirements

With the implementation of MultiConsoling® technology, several requirements could be performed at the same time: Thanks to an intuitive user interface, effortless handling of the entire control room operation is now possible. With only one mouse and one keyboard per workstation, all systems can be used in a flexible manner. Project manager Lars Janßen particularly likes the so-called MouseHopping, with which the cursor slides directly from the workstation monitor to the displays of the video wall.

Virtual machines comfortably integrated

Even virtual machines could be easily integrated into the control room applications via MultiConsoling®. The GrabberVM® enables comfortable integration and establishes the connection to desired sessions.

NWKG control room before and after renovation

Maximum availability as the top priority

Another requirement that JST performs with the new control room: Maximum availability is the top priority for the operation of the cavern facility near Wilhelmshaven. Lars Janßen: “We have set up highly available technology here. That is of great importance to us.” All systems were designed with full redundancy. Corresponding service level agreements and PSM (Proactive System Monitoring) provide additional security.

Unsere Referenzen heute (Auswahl)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)