Photo 1 | JST Control center concept: Flexible, event-oriented control and alarm technology, modern Large screen cubes and ergonomic furniture – with the new equipment by the control room professionals from JST – Jungmann Systemtechnik®, the network control center of ovag Netz GmbH can convince both technically and visually.

Photo 2 | The network control center of ovag Netz GmbH is also located under the roof of the ovag Group's administration building in Bad Nauheim, Hesse.

Photo 3 | Workstations with a confusing number of monitors and insufficient ergonomics. "We have been thinking for years about the need to modernize the control center," says project manager Christian Weber.

Photo 4 | JST control center: The new workstations for the operators in the ovag network control center. Ergonomic desks and chairs, flexible control technology as well as a considerably reduced number of monitors are only some of the many optimizations that were achieved with the upgrade.

Photo 5 | JST control room planning: Virtual visit to the new control center using a professional 3D visualization…

Photo 6 | ...and the implementation of the previous plans into reality.

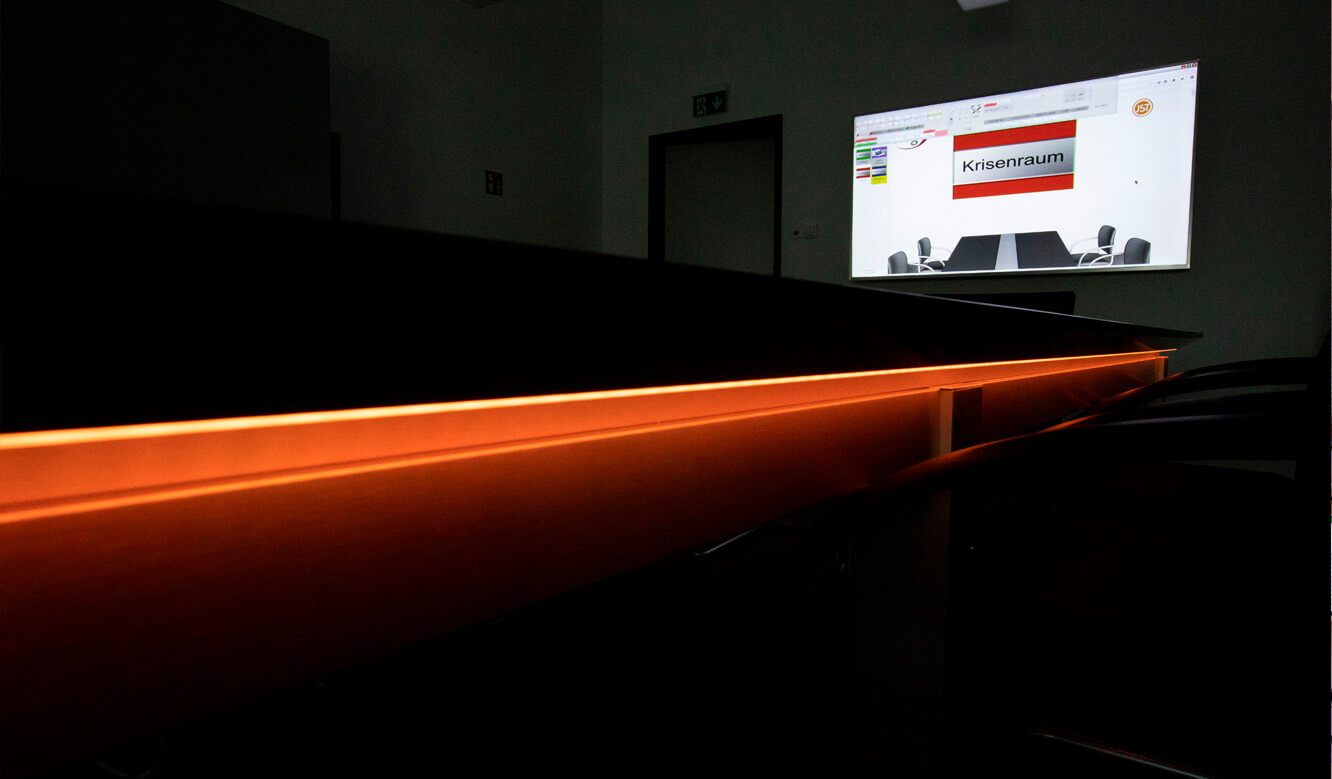

Photo 7 | JST control room concept: The same viewing angle used on the previous motif with changed lighting - the AlarmLight on the Stratos X11® OperatorDesk and the DisplayWall is controlled by a key combination; the colors can be freely and intuitively selected.

Photo 8 | JST 3D planning: Photorealistic 3D studies provided planning security right from the start of the project. Both the employees and the management were therefor able to take simulated tours of the new control center in advance.

Photo 9 | JST control center planning: After the installation was completed, it was clear that thanks to the 3D planning, the operators were able to get a true-to-life picture of what their future view from the workstation onto the monitor wall would look like.

Photo 10 | JST control center concept: Another 3D view from the Planing for the new ovag network control center…

Photo 11 | …and their detailed implementation in reality.

Photo 12 | JST control room desk: The topic "Ergonomics" also played an important role in the installation of the new network control center. Here, for example, with back-friendly work tables that allow infinitely variable height adjustment by electric motor.

Photo 13 | JST Operator table: The control room tables of the Stratos series allow a change between sitting and standing height and thus prevent damage to health. "There are a number of colleagues who like to use this option. I am one of them myself," says project manager Christian Weber.

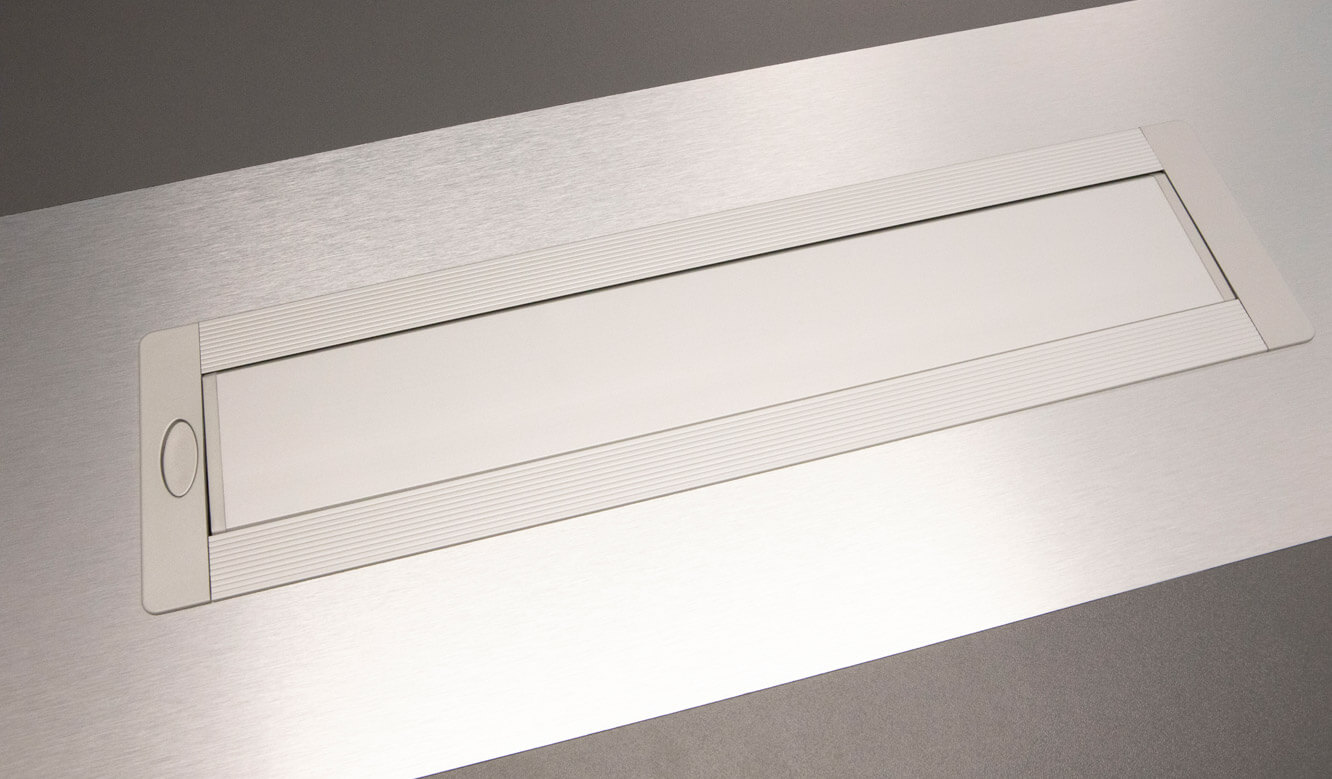

Photo 14 | JST Operator desk: The special Stratos X11® OperatorDesks (here the model "Curve") are equipped with inspection flaps for spacious and illuminated supply rooms...

Photo 15 | ... there is room for a large amount of cables and technical components - a special feature that standard work tables do not offer.

Photo 16 | JST Furniture: Just JST quality - the side parts of the Stratos X11® OperatorDesks with seal of approval in brushed stainless steel.

Photo 17 | JST Furniture: The high demands placed on modern control room furniture are evident in every detail at JST - here brush head seals for cable entry at any point on the height-adjustable Stratos X11® OperatorDesks.

Photo 18 | JST monitor articulated arms: The workstation monitors are attached to the OperatorDesks with height-adjustable 3D articulated arms. They allow an ideal and individually adjustable viewing angle and viewing distance on all displays through a parabolic arrangement.

Photo 19 | JST PowerPort-Data Box: The Operator panels were equipped with PowerPort data boxes. The users have the desired supply connections conveniently available directly at the workstation. Added bonus...

Photo 20 | ...this practice-oriented solution: The change of the personal keyboards and mice used by the shift workers can be done comfortably within seconds, without the tiresome search for the necessary connection options.

Photo 21 | JST Furniture:The furnishing outside the actual control center was also taken over by JST. Here the reception desk with BackOffice Desk, which is used for fault reception and was deliberately outsourced in order to ensure quiet and concentrated work in the control room.

Photo 22 | JST Furniture: Special solutions are one of the strengths of JST, especially when it comes to customer requirements for furniture. Here for example special sideboards with personality cases for the employees.

Photo 23 | JST Furniture: Lockable storage compartments enable every employee to safely store his or her personal belongings even when not on duty.

Photo 24 | JST Conference table: Created exclusively for JST by leading furniture designers: the AllMedia Multifunction table. Thanks to integrated connector panels, notebooks and other devices can be connected directly to the AllMedia meeting table.

Photo 25 | JST Conference Room: Thanks to networking via MultiConsoling®, the employees in the crisis room have access to all data of the control center. In the event of an incident, work can be continued in the control center while the neighboring crisis team takes care of current tasks.

Photo 26 | JST Conference room: Even in the crisis room, the AllMedia conference table was equipped with the colored AlarmLight, which visually informs the employees immediately about possible disturbances in case of an emergency.

Photo 27 | JST Cube giant screen: TheVideo wall the ovag network control center consists of twelve 50 inch large cubes. The image area of the individual cubes is almost frameless. The frame width is only 0.3 mm. This allows Big Pictures to be displayed across several Cubes without disturbing frames.

Photo 28 | JST Consulting: In addition to the visit to the control room simulator, JST places particular emphasis on on-site consulting. JST consultant Oliver Bender (right), here with project manager Christian Weber (center) and operator Oliver Tag: "For me, an open and attentive relationship with our partners is very important. Only in this way can we achieve the satisfaction of our customers that we desire".

Photo 29 | JST Videowall: The Cladding of the large screen is used for the decorative installation of the Cubes and the acoustic and thermal insulation. The special panels in acoustic design support noise reduction in the control center. Behind the stainless steel design strips, the AlarmLight also ensures that employees are visually alerted in the event of an incident.

Photo 30 | JST large screen wall: Thanks to the audio system integrated into the large screen wall cladding, employees are also made aware of an event via acoustic signals when an alarm is triggered.

Photo 31 | JST large screen wall cladding: In the ovag network control center, the large screen wall cladding not only reduces the noise level in the control room, it also offers additional storage space thanks to its multifunctional equipment with glass folding doors.

Photo 32 | JST large screen wall cladding: Behind the glass doors there is space for technical components, for example.

Photo 33 | JST large screen technology: Rear view of the cubes, which can be accessed for maintenance via an inspection corridor.

Photo 34 | JST MultiConsoling®: The JST MultiConsoling® offers the greatest possible flexibility and even reduces the monitors at the workstation to an absolute minimum. All important systems thus remain within the operator's narrow field of vision.

Photo 35 | JST MultiConsoling®: With the graphical MultiConsoling® user interface myGUI® (screen left) the consoles of the operators desks and the large screen wall are shown as “Control room image”. All required sources are shown on the side and can be dragged and controlled by the operator via customizable icons onto any screen at the workstation or large screen wall with a simple mouse click.

Photo 36 | JST Service: For Jungmann consultant Oliver Bender (left), the visit after the installation is also part of good cooperation. Here in conversation with project manager Christian Weber about the advantages of JST Systems “ControlRoom-Automation“, a technical component that makes it possible to acknowledge alarms, open doors or, for example, switch lights on and off at lightning speed via a button bar in the user interface of the operator panels.

Photo 37 | JST ControlRoom-Automation: Via the so-called CommandButton, which is integrated into the user interface of the operator consoles, any scenarios can be triggered.

With MultiConsoling® the future starts in the network control center

A lack of ergonomics, a confusing number of workstations, equipped with a confusing number of monitors, plus disappointing room acoustics and air conditioning – the picture presented to visitors to the former control room of ovag Netz GmbH in Bad Nauheim, Hesse, has little in common with its current status. Thanks to the cooperation with the control room experts from JST – Jungmann Systemtechnik®, the network control center was completely “turned upside down”. The result: a 24/7 control center with an adjacent crisis room that is convincing in every respect, both technically and visually.

While the operators in the control center operated by ovag Netz GmbH check in accordance with the latest legal requirements whether water and electricity are reaching their customers – mostly municipal networks – in the desired way, they had to make do with technical conditions that were once part of the status quo some 20 years ago. ” We have already been thinking for years about the need to modernize the control center,” remembers Christian Weber, Head of Network Management and responsible for construction and operation, among other things.

Later users involved from the beginning

A tip from a colleague drew his attention to the control room team of Jungmann Systemtechnik. Initial contacts led to a visit to the JST Control room simulator. Christian Weber: “I wanted to involve the future users in the development process right from the start. That’s why I deliberately brought along particularly critical colleagues to the control room simulator”.

Intuitive operation and functionality convince

After initial tests, the project manager and his staff were convinced: “The MultiConsoling® is a truly brilliant product.” The operator crew was particularly taken with the intuitive controls. ” During my research on the German market, I have not been able to find anything that even comes close to this functionality and ease of use.” reports Christian Weber. With the help of informative 3D visualizations, the ovag management could also be won over to the idea of a cooperation with the JST specialists.

ovag Netz GmbH – Network control center before and after modernization

All systems can be operated with only one mouse and keyboard

These days, not only the frequent visitor groups in the network control center can enjoy the image of a highly modern control room, but in particular the employees benefit from the extensive update in their daily work: an event controlled cube large screen wall provides TeamView in the control room and, in combination with the MultiConsoling® control technology, enables a reduction to only three monitors per workstation. Christian Weber: “It’s great that we can activate the systems simply by clicking on the desired monitor. No more switching between places. And all this with just one mouse and one keyboard. The times when you always had the wrong mouse in your hand are definitely a thing of the past”.

Less heat and noise, but maximum safety

In addition, thanks to the MultiConsoling®, two more birds could be killed with one stone: By outsourcing the hardware to an external technical room, noise and temperature loads in the control room were significantly reduced. Since the ovag network control center is also a control room evaluated according to critical infrastructure (CI) standards and ISMS (Information Security Management System) certified, the systems are now securely stored behind closed doors. Only authorized personnel have access here.

Excellent rating for project and implementation

Add to this the advantages offered by the ergonomic control room furniture from the Stratos range and you have a control center that is perfectly equipped to meet the demands of users and the requirements of the future. “Products, project flow and implementation – everything is flawless,” concludes expert Christian Weber. “In terms of a percentage scale, I’d give JST a 99. And the rest we could always work out.”

Equipped for the requirements of the future

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWhat hurdles are there on the way to the perfect control center? Which requirements must be taken into account? And how can an experienced partner provide support? A visit to the new network control center of ovag Netz GmbH in Bad Nauheim, Hesse, provides answers.

Press review

Unsere Referenzen heute (Auswahl)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)