Photo 1 | JST control room technology: Was actually planned as a proof of concept (POC) for the duration of a few months: The “Multidesk” project will be continued in the future at the request of the employees in the control room of the Dutch RWE gas -fired power plant “Clauscentrale C”. What's more, the installation of the JST control room experts will serve as the basis for the development of a blueprint for RWE energy control rooms in Europe.

Photo 2 | The “Clauscentrale C” gas-fired power plant houses a control room whose infrastructure is used to control further power plants in the Netherlands. The plant was named after Prince Claus of the Netherlands, who officially opened the facility in 1978.

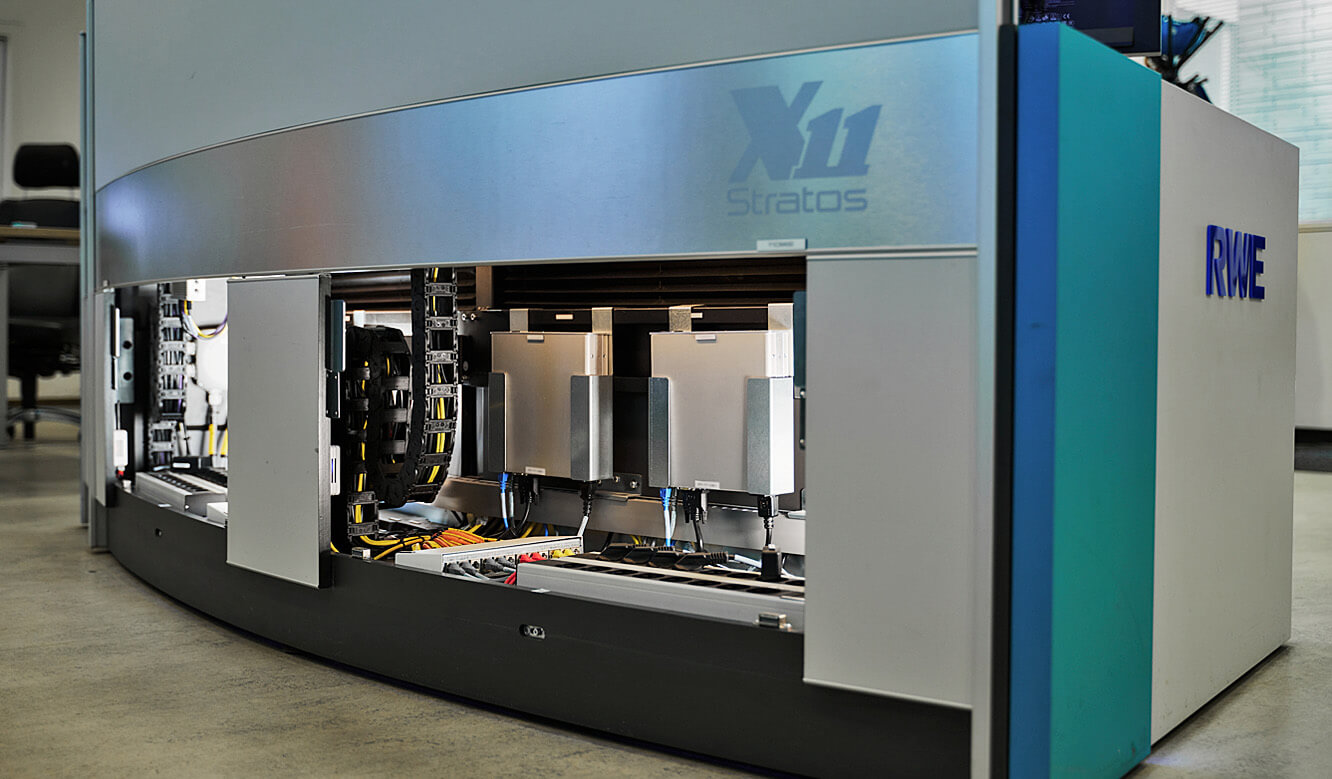

Photo 3 | JST control room equipment: A single workstation that enables the operator to switch on and operate all desired sources - employees at the Stratos X11® control room console are also able to access the applications of other gas-fired power plants in the Netherlands via the KVM technology MultiConsoling®.

Photo 4 | View of the former control room at the Maasbracht site: a fixed monitor for each source being monitored. This combination was no longer sustainable as the number of monitoring tasks increased.

Photo 5 | The central control room of the “Claus” power plant after the JST installation. The focal point of the room is the Stratos X11® operator console from Jungmann Systemtechnik; here in the semi-circular “Curve” version. The special feature: The operator at this workstation is able to call up and control any source of different gas-fired power plants within the Netherlands on any monitor using just one mouse and keyboard.

Photo 6 | Also one of the supporters of the further development of a blueprint for the establishment of remote control rooms within the RWE Group: Dr. Hannah Sommer (Manager Operations Claus Power Station)

Photo 7 | Like his colleagues from Operations, Tom van Rossenberg (Team Leader Operations-A) was immediately “hooked” on the MultiConsoling® from JST. The KVM system enables the control room team to jointly monitor both the local gas-fired power plant on site and other RWE Generation plants within the Netherlands. A positive side effect is that the employees can support each other. The transfer of know-how creates new synergy effects.

Photo 8 | JST control room console: Offers much more than an ordinary work desk: In addition to the software-controlled AlarmLight, the Stratos X11® control room console also has an integrated card reader for a convenient and secure log-on and log-off process via the JST myLogin® software.

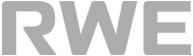

Photo 9 | As a leading Business Support Engineer, Marcel Bleeker can certainly be described as a “creative out-of-the-box thinker”. He has worked intensively on the technical components for the proof of concept and adapted them specifically to the needs of RWE control rooms.

Photo 10 | JST operator console: Marcel Bleeker also thoroughly tested the extensive technical installations located in the supply room of the Stratos X11® operator desk.

Photo 11 | JST control room desk: The generously dimensioned and illuminated supply room of the Stratos X11® operator desk offers space for multi-consoles and other components of JST's KVM technology. For this special project, the “inner workings” of the Stratos were even fine-tuned by the experts at Kessler.

Photo 12 | JST CommandPad®: The JST CommandPad®, shown here in the mobile version, is one of the key tools that provide both a high level of convenience and additional safety through faster reactions in control room management.

Photo 13 | JST myGUI® platform: Clear and user-friendly! The JST CommandPad® with the myGUI® surface displays the control room infrastructure as an individual 3D layout. With the touch of a finger, users can intuitively operate workstations, video wall technology, cameras, meeting rooms, lighting, media, air conditioning and building technology.

Photo 14 | JST Technik: Marcel Bleeker not only appreciates the flexibility that has been achieved thanks to the technical installations from Jungmann Systemtechnik. He was particularly convinced by the intuitive handling of the new KVM technology during the “familiarization phase” of his operator colleagues: “Training for our operators? Not necessary! The new technology was logical for our colleagues right from the start and they all got to grips with it very quickly. Honestly? We only needed five minutes. That was all!”

Photo 15 | JST control room technology: The real “magic” takes place behind the scenes: Cleanly installed technology is located in an external technology room. This keeps heat or noise pollution away from the control room.

Photo 16 | JST myLogin® software: One of the key components for convenient login and logout at the workplace is the JST myLogin® software. The myGUI® Controller enables the implementation of individual rights and role management.

Blueprint for centralized monitoring and operating of energy control rooms

They are considered reliable and flexible and are the key bridging technology for the transition to renewable energies. Gas-fired power plants play a key role in electricity generation. In the Netherlands, gas is even the leading energy source. However, gas-fired power plants have one major drawback: high operating costs, which are partly due to the decentralized monitoring of the plants. RWE Generation, a wholly-owned subsidiary of the RWE Group, is breaking new ground here. Knowledge, expertise and plants are being pooled. Remote monitoring via KVM is the magic formula for greater efficiency that RWE experts have developed with the support of the Jungmann team.

A blueprint for efficient handling. A guide to the centralization of monitoring in power generation. Marcel Bleeker (Sr. Business Support Engineer at RWE Generation) is the driving force behind this project. Dirk Lüders and Rafael Paltian, both consultants from the team of JST control room experts, are also working intensively on the blueprint for the conceptual development of remote operating within the RWE Group. The declared goal: an instruction manual on the basis of which not only gas-fired power plants in the Netherlands are controlled from a central control room. In addition, energy generation from wind, sun, water and battery storage at various RWE locations in Europe is to be monitored remotely.

Too confusing! Time was ripe for KVM technology

But how did this cooperation come about? Marcel Bleeker remembers the initial situation very well: the “Clauscentrale C” gas and steam turbine power plant (named after Prince Claus of the Netherlands) in the south of the Netherlands was responsible for monitoring and operating the plant on site. However, other gas-fired power plants in the country were also monitored by the “Claus” employees in Maasbracht. While the number of applications in the control room was initially manageable, more and more sources were added with new plants. The overview suffered. The traditional motto “a fixed monitor for each application” was no longer workable. The time had come for KVM technology (KVM = keyboard, video, mouse).

Control Center before and after renovation

Virtual meeting in the control room simulator

“We needed more flexibility. We needed a KVM system,” says Marcel Bleeker, adding with a twinkle in his eye. “That’s when Google became my best friend.” His extensive research was rewarded when he came across JST’s MultiConsoling® technology. Together with a large audience of RWE representatives, Bleeker virtually “visited” the control room simulator of the monitoring center experts just outside Hamburg and let himself be transported into the world of modern operations centers.

Quickly and intuitively familiarized with new technology

“Everyone was so enthusiastic afterwards. The feedback from colleagues was: “When can we finally get started?”, reports the engineer, who still remembers the initial phase of the project well: “Set-up and technical installation progressed quickly. The best thing: training for our operators? Not necessary! The new technology was logical for our colleagues right from the start and everyone got to grips with it very quickly. Honestly? It only took us five minutes. That was all!”

Operators request: test setup becomes permanent solution

The initial test setup – consisting of a Stratos X11® control room console, JST CommandPad® and various hardware and software components from the JST portfolio – ultimately became a permanent solution at the request of the “Claus” employees. In the meantime, further workstations have been equipped with the KVM upgrade by MultiConsoling®.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information“Multidesk” is a guideline for other RWE divisions

Other divisions of the RWE Group are now benefiting from the experience gained in Maasbracht. One example is the control centre for offshore wind energy on the North Sea island of Heligoland. The results of the “Multidesk” project were also taken into account here. Marcel Bleeker: “We had so many different solutions in the past. We wanted to arrive at a standard that is not based on a product, but on a philosophy. We consider lighting, acoustics, furnishings and especially KVM technology. With this document in hand, we can say to those responsible for new projects: “Hey, if you want to connect, if you want to control something remotely, from another location, then this is the document you should follow.”

Update: Blueprint is being developed further

Focused on new developments and optimizations, the project group around Marcel Bleeker continues its work. Control room expert Dirk Lüders from JST comments: “Our newly developed JST MultiStreaming®, a network-based KVM-over-IP solution, opens up additional, far-reaching possibilities that we are incorporating into the follow-up of the Multidesk guideline. This will definitely be interesting for new central control rooms, but perhaps also as an upgrade for existing monitoring centers.”

Unsere Referenzen heute (Auswahl)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)