Steel industry: New process control rooms are the "salt in the soup”

A handful of manganese, some silicon and a pinch of niobium. What sounds like a recipe at first glance comes from the “kitchen” of the steel industry. But making steel is not quite as simple as preparing a tasty meal. Salzgitter Flachstahl GmbH (SZFG) offers its customers around 450 different steel grades. This requires complex processes that take place in ultra-modern facilities. Two of these plants on the company premises in Salzgitter have now been equipped with new process control rooms – by JST – Jungmann Systemtechnik®.

“This plant meets the requirements for ultra-low desulfurized, ultra-low decarburized and hydrogen degassed steels as well as for steels with the highest degrees of purity,” explains steel mill manager Thomas Müller, describing the advantages of the new RH plant (Ruhrstahl-Heraeus), a vacuum treatment plant used in secondary metallurgy to increase the quality and capacity of high-grade grades.

Only as efficient as the person who operates them

But even the most modern instruments and equipment are only as efficient as the people who operate them. For this reason, SZFG decided to use a control station from Jungmann Systemtechnik to operate and control the new RH system. And not only that: At the same time, a new control room was also installed for the upstream process of hot metal desulphurization and the plant required for this.

High-tech plant with a high-tech control station

For plant engineer Soeke Helmers, the cooperation with the JST specialists is an important step: “A new high-tech plant includes a high-tech control station that offers an optimal combination of technology and design”.

Most exact monitoring and control required

But what actually happens in the new RH plant? And what are the tasks of the 24/7 manned control center? The Ruhrstahl-Heraeus process is a complex process in which the liquid steel is decarburized by means of vacuum treatment. At the same time, unwanted gases are extracted from the melt. Soeke Helmers comments: “There is a large number of process models here, which are precisely monitored and controlled to calculate the desired result. Naturally, we want the operator to have an optimal overview of everything.

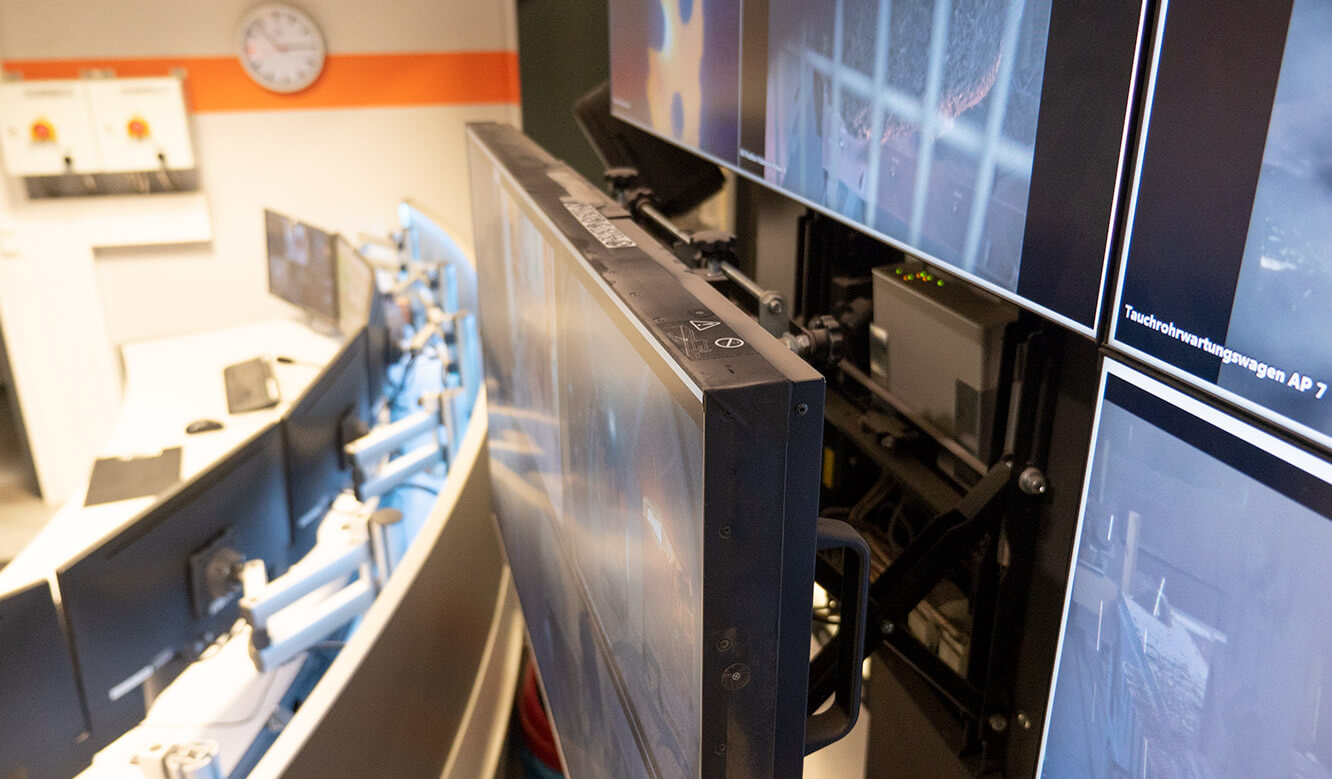

Safe and intuitive with MultiConsoling®

Large screens walls provide an overview of the processes. Whether camera view, logistics model or data for metallurgical calculations – with the JST control concept MultiConsoling®, the employees at the control stations are able to safely and intuitively access any desired display on the displays of the large screen wall or the individual workstations via the myGUI® graphical user interface. “This allows the employees to evaluate the process perfectly,” judges Soeke Helmers, who emphasizes: “This is not just a monitoring activity. Rather, modern technology in combination with human expertise and years of experience are required. “Our employees know exactly how to handle the melt. Important decisions are made which have a major impact on the final product.”

New standards in work ergonomics

In order to provide the best basis for judgment and overview for these essential tests and diagnoses within the framework of a high degree of automation, the process control stations of Jungmann Systemtechnik were implemented. “We also wanted to set new standards here in terms of work ergonomics,” says the plant engineer, who mentions several aspects that are particularly appreciated by his colleagues from the control room team. These include the Stratos X11® CommandDesks, which, thanks to height adjustment, special supply rooms for cables and technology as well as indirect lighting, can be easily set up to meet the individual requirements of the individual.

"Desired configuration easily available”

It is precisely these customization options that the steel expert appreciates in another JST component that has found its way into the new process control rooms: With the ControlRoom-Automation solution, every employee can optimally compile views of all data, functions and camera images, then save them and call them up again at the start of the shift at the push of a button on the operator console. “So you can have the configuration you want quickly and easily available.”

Praise for process transparency thanks to JST concept

The conclusion of Soeke Helmers: “The control station concept of Jungmann Systemtechnik offers excellent process transparency and also advantages for work safety. Furthermore, the satisfaction of the employees speaks for itself, for whom this great working environment is very important.“

Our references today (selection)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)