Photo 1 | JST control room: An efficient control room with ergonomically designed workstations – the request of VA Erzberg GmbH for their new control room was fulfilled in all respects by the JST – Jungmann Systemtechnik® team.

Photo 2 | Explosive spectacle: One blasting can extract about 50,000 to 80,000 tons of rock. The following individual processing steps are controlled by the new control room.

Photo 3 | Fully automated processing in the fine ore storage. "Every machine that rotates and moves here is monitored from the control room," explains project manager Ronald Käfmüller.

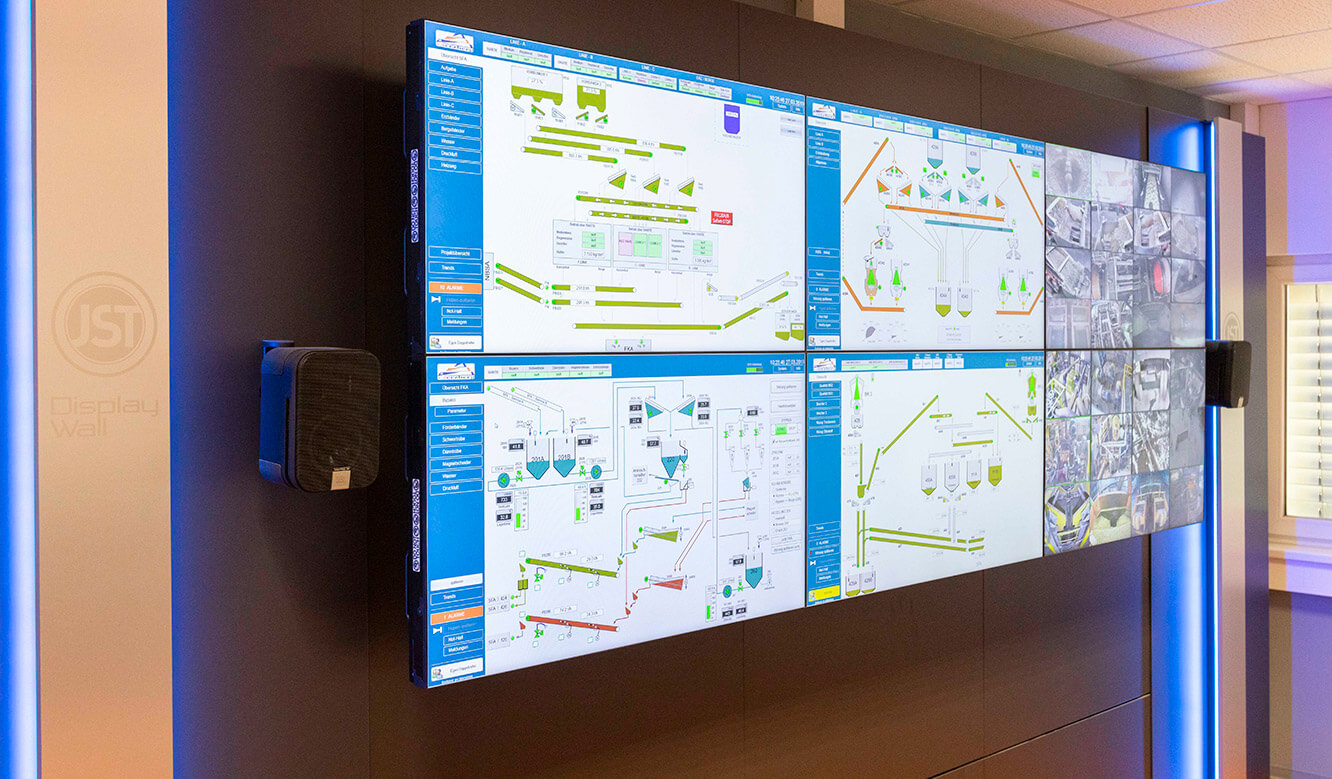

Photo 4 | JST control room: The entire ore dressing process with 48 conveyors and 76 camera settings is monitored in the control room. With the solutions of JST – Jungmann Systemtechnik® a working environment could be created that makes the work in the control room interesting especially for young employees.

Photo 5 | JST Furniture: Design award winning control room desks "Made in Germany". – Optical details such as the stainless steel logo also make the control room equipment a visual experience.

Photo 6 | JST CommandDesk: The control center desks offer numerous ergonomic advantages. In addition to generous legroom and a particularly deep table top, this includes in particular the electromotive height adjustment, ...

Photo 7 | JST operator desk: ... that allows you to switch between sitting and standing, for example. Each operator can adjust “his” Stratos X11® CommandDesk to his individual needs.

Photo 8 | JST control room desk: The electrical height adjustment of the Stratos X11® Control room desk is conveniently carried out via a pull-out control unit under the table top.

Photo 9 | JST OperatorDesks: The Stratos X11® OperatorDesk - here in the curved version "Curve” - not only meets the highest ergonomic and optical demands, ...

Photo 10 | JST control room desks: ...behind the inspection flaps are generously proportioned, illuminated supply rooms which, thanks to cleanly installed technology - without visible cables - offer a perfect appearance.

Photo 11 | JST TFT columns: TFT columns with height-adjustable 3D monitor articulated arms in a concave arrangement offer the user an optimal field of view.

Photo 12 | JST AlarmLight: The control room at VA Erzberg GmbH relies on well designed technical solutions - the AlarmLight behind the monitors can be adjusted as needed and can change color in critical situations according to events.

Photo 13 | JST furniture: The high demands made on modern control room furniture are reflected in every detail at JST - here brush head seals for cable entry at any point on the height-adjustable Stratos X11® OperatorDesks.

Photo 14 | JST PowerPort-Data Box: Flush mounted in the surface of the Stratos X11® OperatorDesks: the PowerPort-Data Box, that…

Photo 15 | …in open state, makes all required supply connections conveniently available directly at the workplace.

Photo 16 | JST Furniture: individual furnishing variants, which fit into the control room environment - JST Furniture Manufacture meets customer requirements with special equipment.

Photo 17 | A look at the former control room from the turn of the millennium makes it clear: technically and ergonomically, the old control room no longer fitted into VA Erzberg's corporate concept. A control room operator had to "juggle" 15 keyboard and mouse units there.

Photo 18 | JST Ergonomics: Thanks to MultiConsoling® operation and modern large screen technology the number of workplace displays could be optimized. The mouse and keyboard units have even been reduced from 15 to one.

Photo 19 | JST DisplayWall: The monitors of the large screen wall and workstation are arranged in a way that the operator can easily keep an eye on all screens.

Photo 20 | JST Large screen technology: The Video wall in the control room of VA Erzberg consists of six 46" business displays with ultra-narrow frames, which, if required, also allow cross-screen display as BigPicture.

Photo 21 | JST DisplayWall: Optical plus point of the so-called DisplaySuits – Design strips of brushed aluminum give the large screen wall the "JST style".

Photo 22 | JST Video wall: Behind every large screen display there is a technical compartment. This allows the displays to rest directly on the panels of the DisplaySuit. Technical installations or cables are nowhere disturbingly visible.

Photo 23 | JST Display technology: With the Quick-Out Mounting System individual displays can be easily pushed forward by light pressure on the outer edges - even during operation.

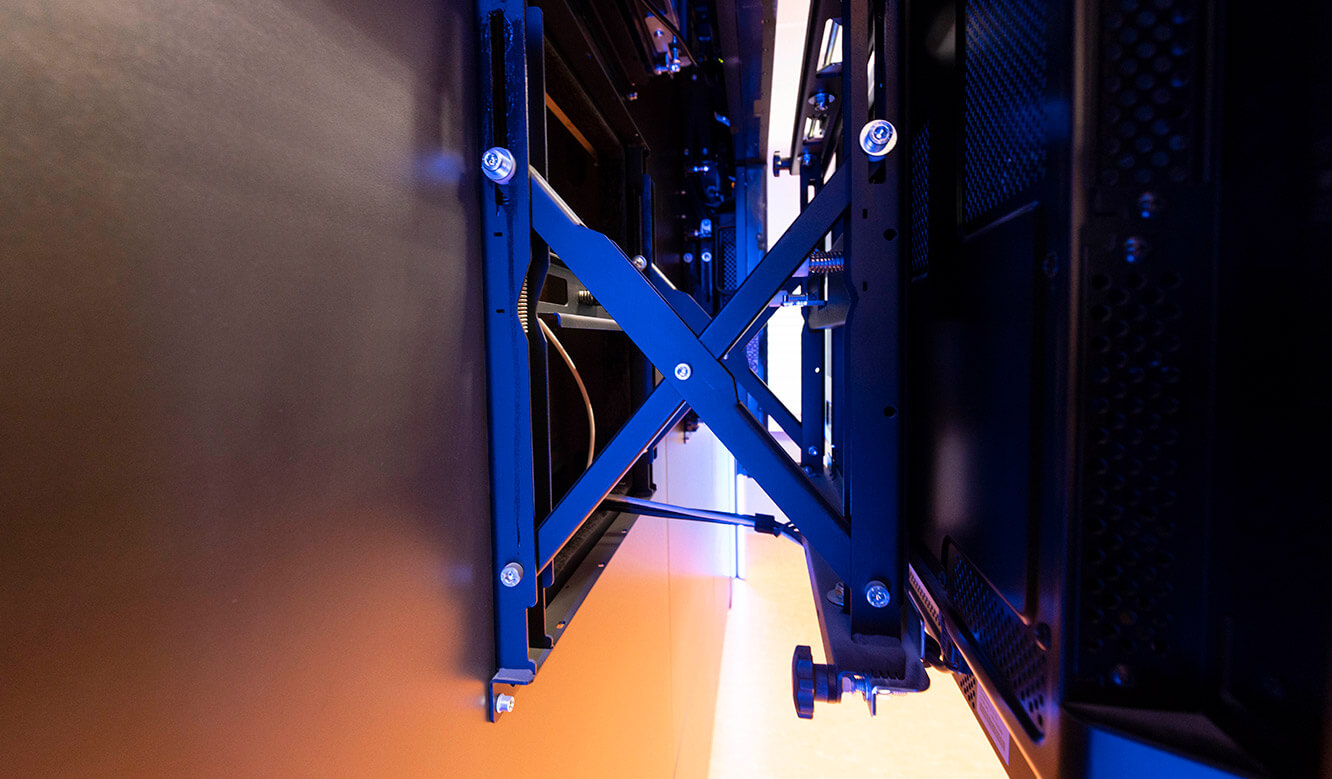

Photo 24 | JST Video wall: The large screen displays can also be installed - as here - on non-load-bearing walls. A special JST support plate is used for load distribution, on which the displays are mounted with movable scissor arms.

Photo 25 | JST AlarmLight: Modern alarm management in control rooms - at the Stratos X11® OperatorDesk and the DisplayWall the lighting changes color event-controlled (e.g. to red) in case of high-priority alarms to signal to the operator that he has to become active immediately. This is made possible by the monitoring software PixelDetetction®.

Photo 26 | JST MultiConsoling®: With the myGUI® user interface (shown here on the right monitor) the large screen starts at the workstation. With MultiConsoling® not only large screens are controlled, but also the monitors at the workstation are switched with all signals (keyboard/mouse/monitor/audio) in real time.

Photo 27 | JST-MultiConsoling®: The heart of the JST MultiConsoling® - the MultiCenter (device at the bottom) also includes components for the JST CockpitView®, the IP-independent cockpit for an overview of the most important applications in the control room.

New mining control room monitors all ore production processes

It is also called “the largest pyramid in the world” – the Styrian Erzberg. After more than 1,300 years of mining history, a total volume of twelve million tonnes of rock, including three million tonnes of pure iron ore, is now produced annually in open pit mining using state-of-the-art technology. To control and monitor the entire extraction and treatment process, VA Erzberg GmbH relies on a future-oriented control room with technical and ergonomic solutions from JST – Jungmann Systemtechnik®.

If we believe a traditional legend, the people of Erzberg need not fear for their prosperity. According to this, the inhabitants of the region caught an Aquarius in ancient times, who bought his freedom with a barter. “Gold for ten years’, silver for a hundred years’ or iron forever,” he said. The wise iron ore workers are said to have chosen the latter, whereupon the Aquarius showed them the ore mountain.

In view: "Every machine that turns or moves"

“Forever there”, however, according to current estimates by experts, means that the ore reserves will last for forty to fifty years of mining. About 230 employees are responsible for the extraction and processing of the raw material at the mining company VA Erzberg. The pivotal point for monitoring and regulating all processes of the entire ore dressing plant: the control room, which has been extensively upgraded with state-of-the-art large-screen technology, a suitable operating system and ergonomic furniture. “Every machine that rotates or moves is monitored from this control room,” explains Ronald Käfmüller, academic preparation engineer and responsible for the process technology of the plant.

From the control room simulator live to the control room

His goal: “We wanted to make the workstations and functions of the control room more ergonomic and efficient. After some initial research, the project manager quickly came across Jungmann Systemtechnik as a qualified partner for this project. With a visit to JST’s control room simulator, unique in Europe, the decision was made. Käfmüller: “There, we were able to connect live to our system in Austria and develop a concept in the control room simulator that served as the basis for our project. This was not only exciting, but also target-oriented. This gave us the opportunity to directly determine which technologies were useful for us and on what scale”.

The control room before and after modernization.

Intuitive operating concept for all processes and cameras

As a result of these intensive consultations, the new control room today has clear presentation of all processes and camera systems on a Video wall with large screen displays, that thanks to the MultiConsoling operating concept® enabled not only a reduction of monitors, but also of the associated mouse-keyboard units: The former 15 (!) mouse/keyboard combinations have been replaced by a single one, with which both the workstation and large-screen displays can be operated via MouseHopping.

“The heat is no longer a problem”

Further plus points in the eyes of Ronald Käfmüller: “In the past, we always had a lot of heat in the control room. With the MultiConsoling® it was possible to relocate the entire technology from the control room. The heat is therefore no longer a problem. “Also for the ergonomic Stratos X11® control room desks the project manager gives the thumbs up: “Many people can build furniture. But this control desk really has it all with the height adjustment, the large technology storage compartments and the ergonomic design”.

Modern process control center attracts the next generation

The company was able to test how well the new workstations in the control room were received by VA Erzberg staff right after implementation. In the course of the installation of the process control room, the last two long-standing colleagues were retired and efforts were made to recruit new employees. “The great optics of the new control center played a decisive role in our search for personnel. This has made it much easier for us to attract young employees,” reports Ronald Käfmüller.

Unsere Referenzen heute (Auswahl)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)