Photo 1 | JST control room planning: workgroup-oriented room planning - the employees in the FIS control room (production and control system) supervise the various systems in front of two monitor walls; from the receipt of orders for the plant to the entry into the assembly line.

Photo 2 | JST planning: A 3D visualisation enabled a view into the new control room during the planning phase. Possible change requests can be easily implemented in this project stage.

Photo 3 | JST control room: During the subsequent construction of the control room, the planned monitor wall was extended by two additional large-format displays.

Photo 4 | JST planning: Photo-realistic planning from JST – Jungmann Systemtechnik®...

Photo 5 | ...and the subsequent implementation of the previous planning into reality.

Photo 6 | JST control room: The operator workstations and large display walls are planned and installed precisely in terms of visual distances and viewing angles.

Photo 7 | JST furniture: Meeting the highest ergonomic requirements for working in control rooms: The JST operator desks from the Stratos line – shown here in a convex arrangement.

Photo 8 | JST control room planning: Thanks to the platform construction, the rear workstations also have an optimal view of the DisplayWall.

Photo 9 | JST workstations: View from one of the rear operator workstations. There is even a clear field of view of the large display wall from here.

Photo 10 | JST Operator desk: Ergonomic aspects have top priority in the control room furniture from JST – Jungmann Systemtechnik®. Here, an operator desk at sitting height.

Photo 11 | JST control room furniture: The same desk as in the previous photo - this time at standing height. Thanks to electric motor's height adjustment, the special Stratos X11® CommandDesks can be adapted to the operator's individual needs; for example, switching between sitting and standing to relieve back strain.

Photo 12 | JST Control Desk: One of many good ideas that were implemented in the creation of the Stratos control room furniture - spaciously designed supply areas offer a perfect look. The Stratos X11® series desks allow cleanly installed technology without visible cables.

Photo 13 | JST furniture: The high standards of modern control room furniture are evident in every detail at JST - here brush head seals for cable entry at any point on the height-adjustable Stratos X11® OperatorDesks.

Photo 14 | JST large display screen: Two rows of four large-format displays (screen size 46 inches) keep the control room team informed about the most important events in real time. JST's PixelDetection® software ensures that the source is detected automatically.

Photo 15 | JST displays: Thanks to JST's business LCD displays with ultra-narrow frames, it is possible to render very large images as Big-Picture across many displays.

Photo 16 | JST QuickOut mounting system: The QuickOut mounting system offers perfect service accessibility - even for displays located in the middle of a Videowall. By applying light pressure to the outer edges of the display, each individual display slides forward (quick-out) to provide access to rear connections and technical components for inspection.

Photo 17 | JST DisplayWall®: Perfect in design and workmanship. Design strips with a high-quality aluminium brushed surfaces and the AlarmLight give the monitor wall the unmistakable JST look. The AlarmLight flashes red for particularly critical alarms.

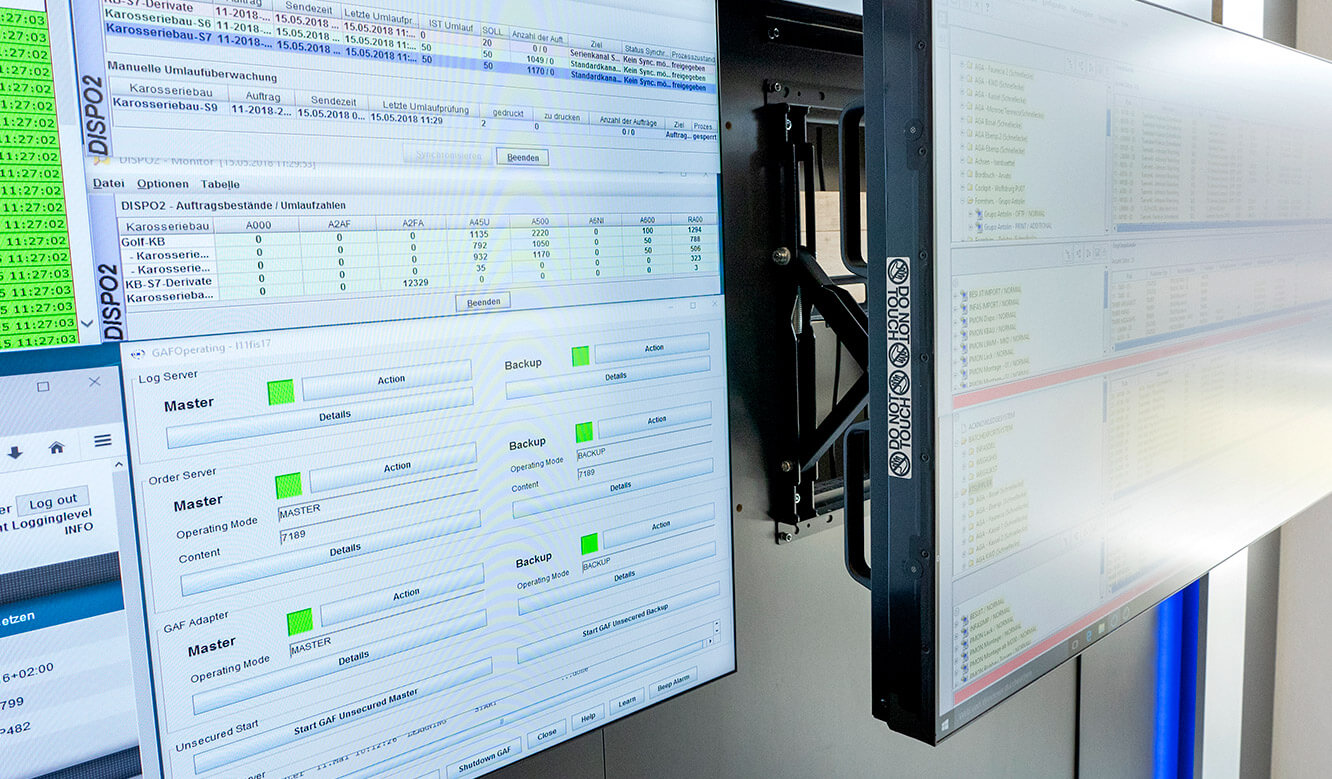

Photo 18 | JST MultiConsoling®: With the easy-to-understand myGUI user interface for MultiConsoling®, any sources can be displayed in real time on workstation monitors, on individual large-format displays or as BigPicture across several large-screen displays. Another special feature: Only one mouse and keyboard are needed per seat to operate everything in real time.

Photo 19 | JST technology: The entire technology was installed in a separate technical room using MultiConsoling®. This results in less heat and noise in the control room.

Digital upgrade for the "brain" at Volkswagen

Within the Volkswagen factory it is called “the brain of the factory”: the FIS control room. FIS – that stands for vehicle information and control system. This is exactly what the Wolfsburg control room focuses on. The entire vehicle production process is monitored and controlled from here; from the receipt of orders for the plant to the entry into the assembly lines. It is easy to appreciate that technology and ergonomics must meet the highest standards. With the support of the control room specialists from JST – Jungmann Systemtechnik®, a comprehensive update was implemented.

“We worked with JST several years ago and equipped the control room with ergonomic furniture and large-display technology,” recalls Hilmar Schimenas, Head of Operational Vehicle Control Room. “Since digitisation is a core topic of the Future Pact, the hardware and software has now been brought up to date with the help of financial resources from Innovation Fund II”.

JST planning: Photo-realistic planning from JST – Jungmann Systemtechnik® and the subsequent implementation of the previous planning into reality.

Optimal software solutions thanks to digitalisation

This enables the Volkswagen Group to take advantage of all the benefits of digital progress at the FIS control room. Schimenas: “We simply wanted to be able to use optimal software solutions that allow us to act quickly.” Prerequisite for this: digital technology.

Proactive alerting with PixelDetection®

With more than 20 systems with numerous monitoring interfaces displayed on two workgroup-oriented monitor walls with a total of 16 LCD displays, it is difficult for the human eye to keep everything in view. This is exactly where “the operator’s eye” – the JST monitoring software PixelDetection® – comes into play. A perfect way to proactively display alarms visually via the AlarmLight. The project manager is convinced: “With PixelDetection®, changes in status are always clearly visible and colleagues can react immediately.”

Most important application at a glance

With the digitisation, the operators of the Wolfsburg FIS control room now also benefit from another JST control room component: JST CockpitView® makes it possible to display the most important applications clearly at a glance. “At the beginning of each shift, we use a default setting with all main views. During the shift the views change of course. But at the end the operator returns to this overview”, Hilmar Schimenas explains about the procedure in the FIS control room.

Constructive sessions in the control room simulator

Looking back, the project manager sees the visit to the JST control room simulator alongside realistic 3D planning as valuable decision-making aids: “I can warmly recommend this to everyone,” says Schimenas, “we were guests there with employees from all three shifts, were able to test the solutions directly on site and decide what is useful for us. This was a really constructive meeting, where you could clearly feel how goal-oriented and competent the JST team works.”

FIS: Production control center - Video

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationPress review

Unsere Referenzen heute (Auswahl)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)