Volkswagen relies on JST control station for automation in body construction

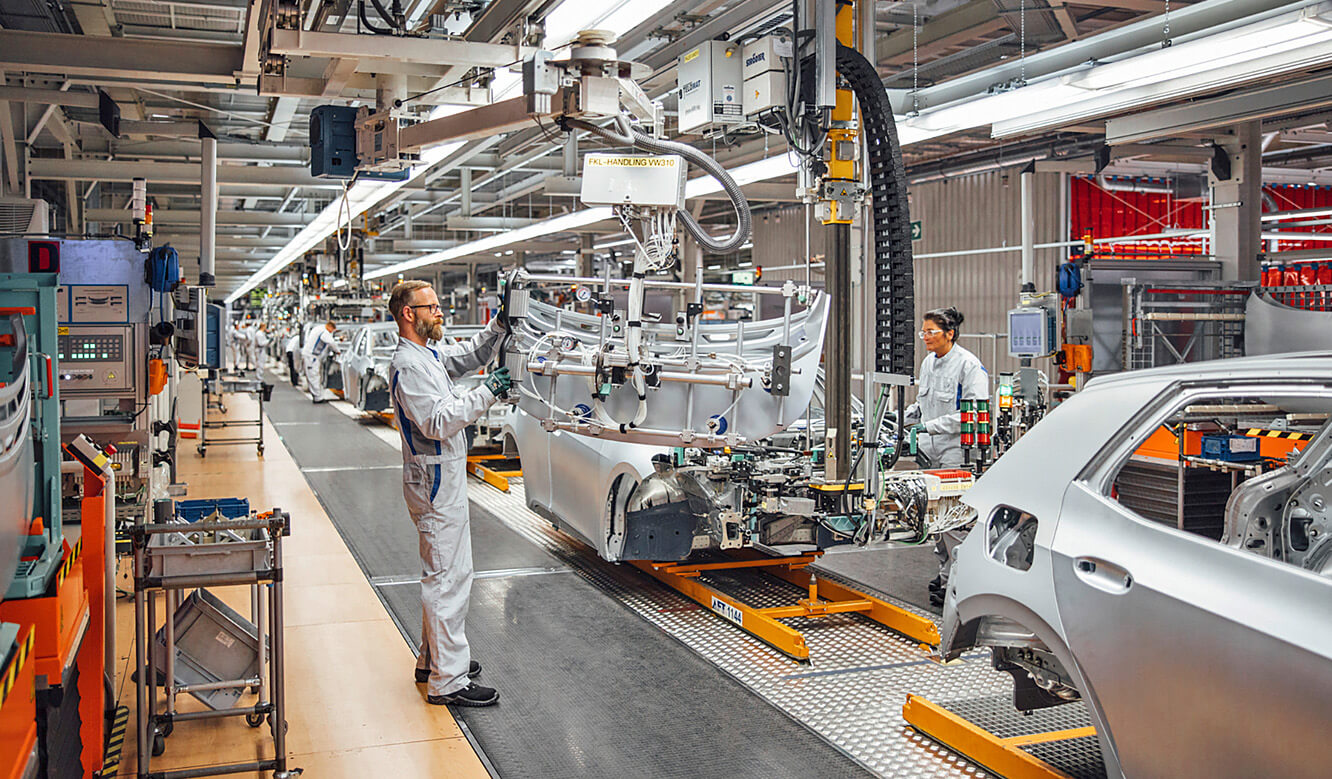

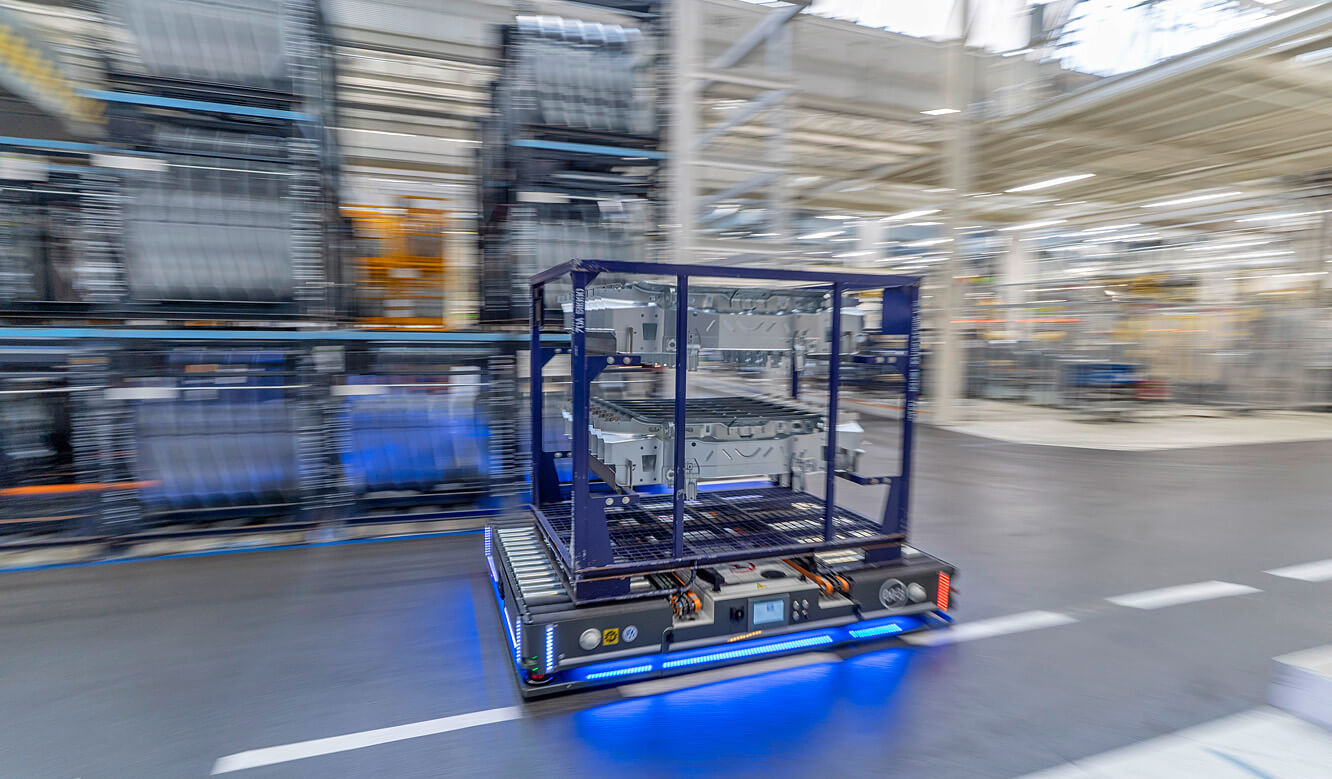

“With around 1,700 robots in body construction and assembly, automated guided vehicle systems (AGVs) and fully automated production processes, Zwickau shows what future-oriented volume production of electric cars looks like today.” This is how Volkswagen Saxony describes the transformation processes for automation at the Zwickau site. However, human input is still required to ensure that the so-called AGVs (automated guided vehicles) can actually drive and do their job. The new body construction control station installed by JST – Jungmann Systemtechnik® is home to a team of AGV coordinators who keep a keen eye on everything.

Whether logistics or intralogistics – the industry has long recognized this: Automation through automated guided vehicles improves efficiency and production throughput, reduces bottlenecks and downtimes. According to the VDI AGV technical committee, “automated guided vehicles are experiencing hype in the wake of Industry 4.0 and the smart factory because they network, organize and optimize.”

AGVs are experiencing a real boom in the logistics sector

AGVs use sensors and scanning systems to navigate autonomously. They recognize their surroundings and move skilfully around obstacles. The vehicles never get tired and are in use virtually around the clock. Compared to manual transportation with forklift trucks, the systems also reduce accidents and transport damage. The pro list is long.. So it’s no wonder that AGVs are experiencing a real boom in logistics with Industry 4.0 and increased automation of work processes in material transportation and handling.

"Core technology on the road to the factory of the future"

At Volkswagen in Zwickau, AGVs are seen as a key element of the digital infrastructure for the factory of tomorrow, in which materials and components for production are delivered just in time and precisely on target. The official statement is: “Automated guided vehicles (AGVs) are another core technology on the road to the factory of the future. They bring the required components to the assembly line on defined routes completely autonomously and thus revolutionize factory processes.”

Visionary control center for an innovative system

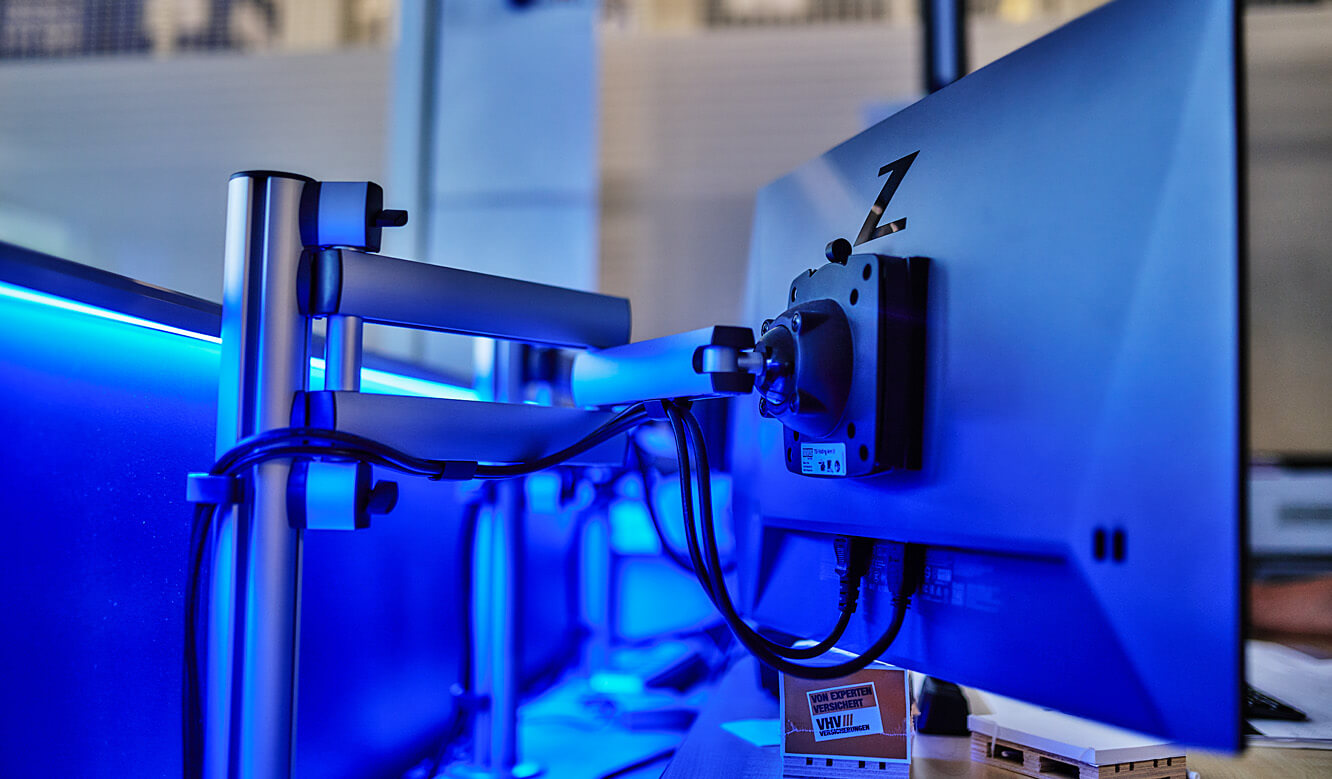

This underscores the importance of monitoring the innovative system through a similarly visionary control center. VW has repeatedly relied on the expertise of Jungmann Systemtechnik. The AGV control station for the body construction ensures that AGVs and supplementary systems for materials management interlock seamlessly. The control station thus covers the entire area of intralogistics for the body construction division.

"We monitor all logistical production processes"

System Coordinator Jens Poling explains the importance of the new control room for him and his colleagues in more detail: “We monitor all logistical production processes in the body construction, across the entire line, from the “body shell layer” to the “body shell exit”. The chain starts with us and leads to the exit in the direction of the paint shop. This is a very complex field, which is why this control station is very valuable to us.”

Fast response to critical deviations

In the past, each operator had three screens at his disposal. “That was clearly not enough for the existing monitoring tasks,” recalls Jens Poling. “Now, with the JST technology and the ability to switch between the large screen wall and displays at the workstation, we have everything in view and can react immediately to changes in the various parameters.”

The status of the systems is continuously visualized

Whether stock levels or parts from external suppliers are insufficient, whether there are problems with a system or an AGV – “we know immediately when a system fails. This is displayed in red and we can see it immediately. As soon as a system turns red, it tells me that there is a failure,” reports the system coordinator.

"The control center is a huge step forward"

Looking back, it becomes clear what the great benefit of JST technology is. ” If a system came to a stop for an unexplained reason in the past, we received a call. That took a lot of time. With the new technology, we are able to detect any faults in advance and react before the line comes to a standstill,” says Jens Poling and continues: “I can speak for all my colleagues. The control station is a huge step forward for us.”

Attractive overall concept: "Everything from a single source"

As IT project manager at Volkswagen in Zwickau, Rico Trautmann points out another aspect: when he came across JST in 2017 through online research, he found “the overall concept attractive and very suitable for us! Everything from a single source – that’s what interested me. We only found this combination of technology and aesthetics at JST.”

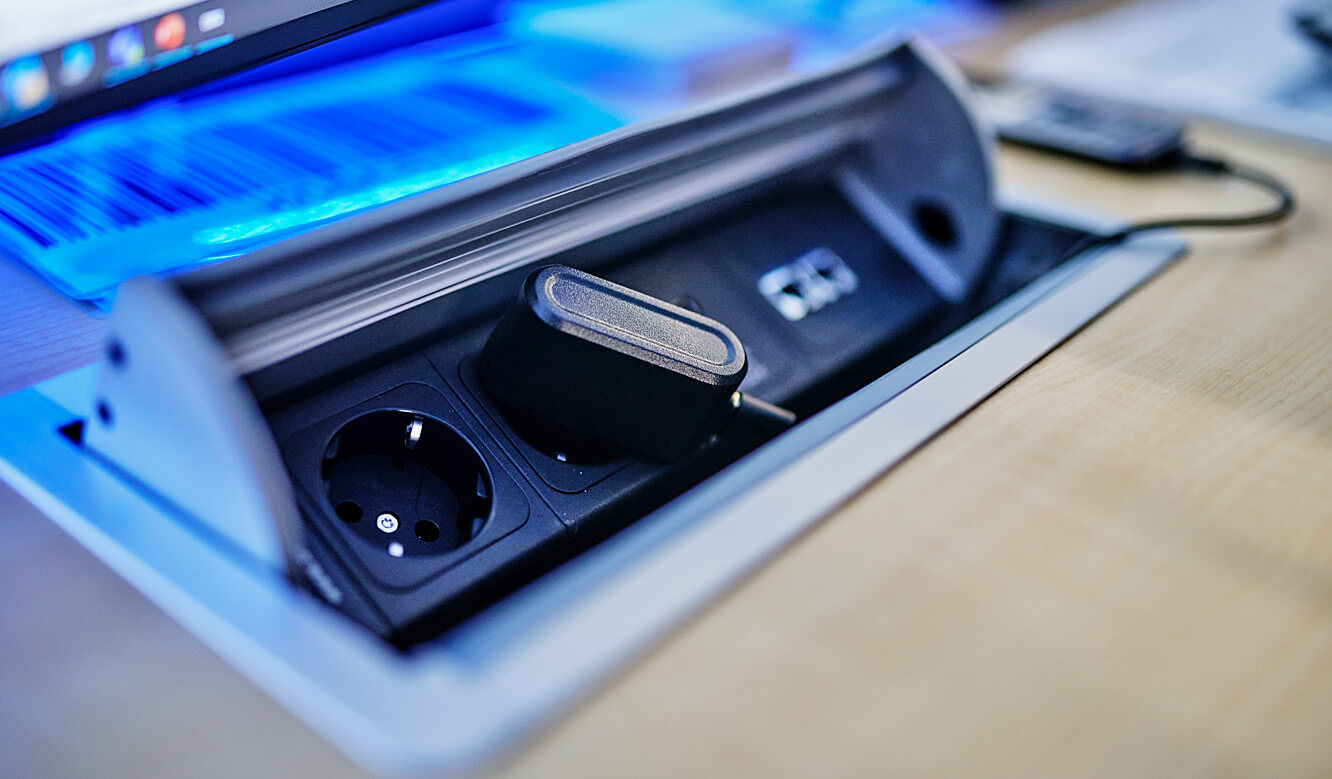

Isolated solution without connection to the Volkswagen network

Over the years, he gained a better and better understanding of the possibilities of control room management with JST components. Rico Trautmann: “We have learned with every project. And now, with the third control center, we are talking to the JST technicians on an equal footing and can formulate our wishes more specifically.” These special VW demands include, for example, the requirement from the car manufacturer’s IT security department to implement the JST technology as a 100% stand-alone solution. There must be no connection to the Volkswagen network. Another important project requirement for Volkswagen was a connection via optical waveguide to bridge long distances and with high interference immunity.

Scalability already taken into account during planning

The experience that the team from the body construction department has gained shows how important it is to take individual specifications and possible scalability into account when planning a control station. Rico Trautmann: “The control center was designed in such a way that future expansions are easily possible. We have provided adequate physical space in the server room and designed the system in such a way that additional visualizations can be added. This approach has proven its worth. The first upgrade was easily implemented just as we had planned.”

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationUnsere Referenzen heute (Auswahl)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner Zement, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)