Warehouse operations center and control center for logistics – design efficient material flow!

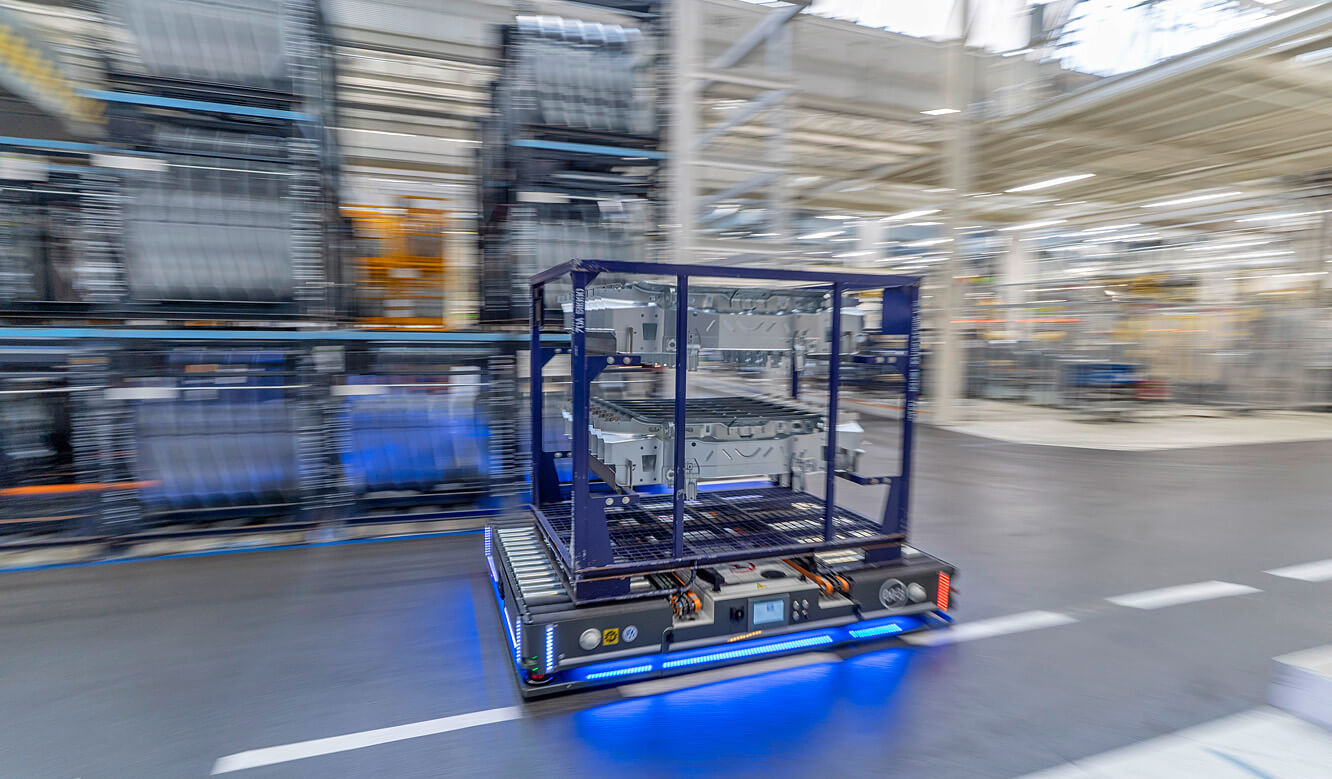

The logistics control center is the cornerstone of every workflow within warehousing. The most important requirements: As the centerpiece of intralogistics, the warehouse operations center ensures efficient control of all material flows thanks to innovative components. Warehouse movements can be tracked transparently in real time and automated processes optimise logistical workflows – from incoming to outgoing goods.

With modern solutions specifically for control centers in the logistics sector, JST is setting standards in the digitalisation of intralogistics.

Centralised monitoring is absolutely crucial in logistics

Are the stock levels correct? Are there any shortages? Are goods being received at the desired speed? These and many other aspects are continuously monitored in logistics centers. Inventory management and warehouse operations are usually handled by automated systems that are bundled and controlled by a logistics control center. However, if there are barriers to the integration of different applications and the operator lacks the necessary overview, this can lead to disruptions in warehouse and material flow processes and thus to cost-intensive bottlenecks.

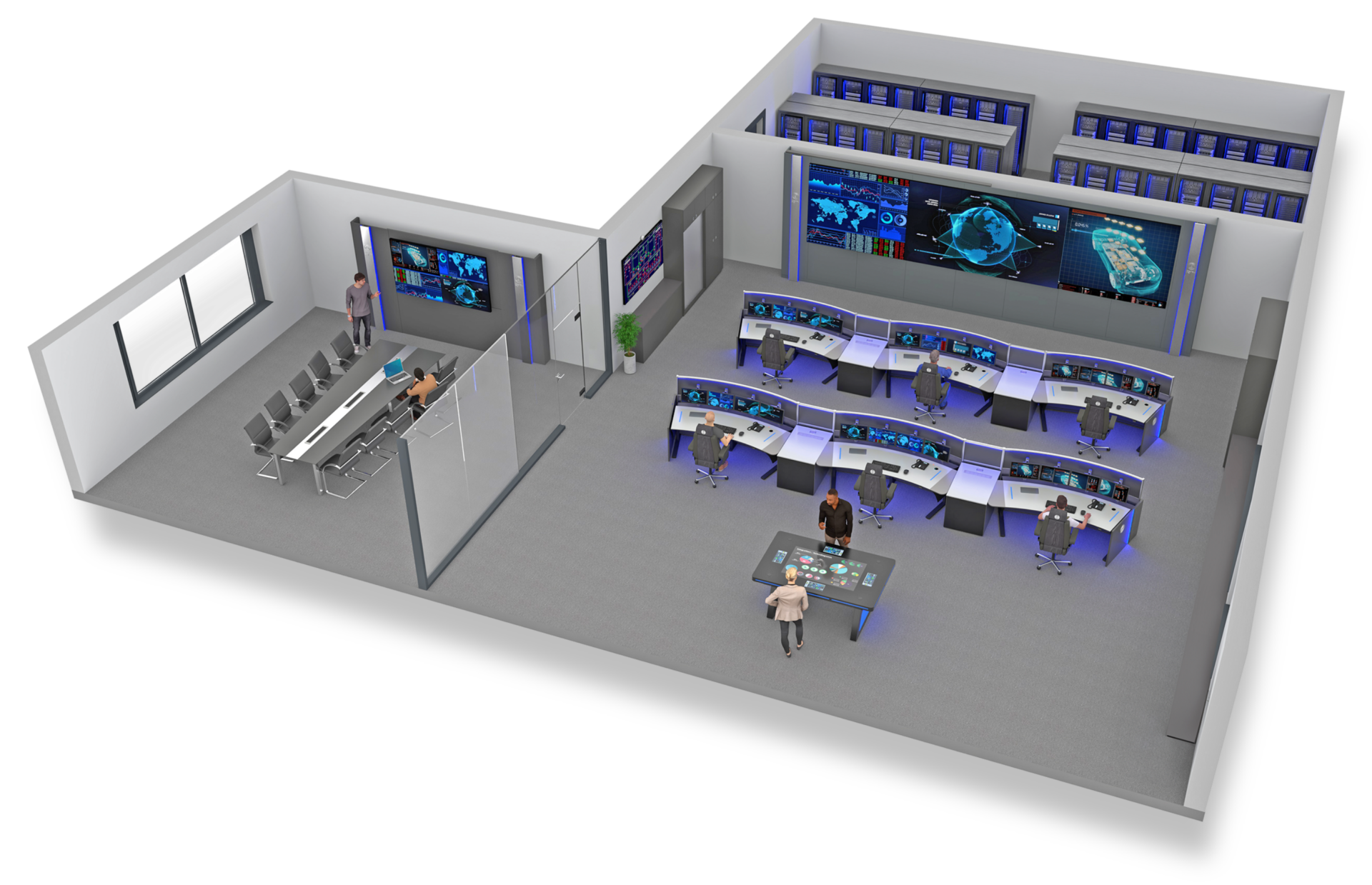

Centralised real-time monitoring is an effective solution for ensuring rapid responsiveness and a comprehensive overview of all stocks in the digitalised logistics sector. The key requirements for intralogistics control centers therefore include large-screen and KVM systems as well as a customised ergonomic concept and smart tools that enable future upgrades.

Increase efficiency, reduce costs. Two core requirements that are met with the JST control room solutions in the warehouse control center. The use of flexible and proactive large-screen technology in combination with intuitive handling of the system control allows rapid intervention – before disruptions lead to delays, bottlenecks or even production stoppages. The centralised coordination of all goods flows prevents idling, delays and downtimes.

‘’At the right time in the right place‘’ – this could be the motto of the materials control center at the Volkswagen plant in Saxony, Zwickau, which has been technically and ergonomically equipped by Jungmann Systemtechnik to meet the requirements of the future. The central task of the operator team is materials management, in other words the planning and control of goods movements.

These reasons speak in favour of a logistics control center made by Jungmann Systemtechnik

Optimised material flow – thanks to digital access to the system control

Efficient use of resources – both in terms of personnel and technology

Automated processes – reducing manual intervention speeds up workflows

Secure handling – intelligent KVM technology simplifies monitoring tasks

Proactive surveillance – automation in fault detection creates safety

How logistics automation creates a competitive edge

The combination of speed, precision and efficiency makes the logistics control center indispensable for warehouse operating structures. Turnkey solutions from the JST control room experts ensure strategies for higher productivity, lower costs and better planning in intralogistics. Companies that rely on modern automation systems can react more flexibly to market requirements and thus secure a long-term competitive edge.

New technologies such as AI-operated systems can be integrated on the basis of JST’s intuitive KVM solutions. Growing requirements are compensated for by modules that are also high-performance, functional and scalable. The result: a future-proof warehouse control center with maximum productivity and cost control.

How to future-proof your control center!

How to future-proof your control center!

Warehouse data in real time with suitable visualisation

Dynamics and flexibility are factors that play a decisive role in a warehouse operations center. The tasks in control stations for logistics include monitoring incoming and outgoing goods, inventory management and warehouse organisation as well as order control and picking, monitoring of transport systems and material flow. Early detection of potential disruptions and bottlenecks is a top priority.

LED walls and LCD video screens prove to be suitable solutions for providing the operator with the best possible conditions for analysing incoming data in real time. The large screen systems from JST offer a flexible and clear display of all applications as well as immediate access to the processes in the warehouse control center.

Fault detection – a question of overview

Fault detection – a question of overview

Here we go! Take control in the “room of the future”

The starting signal for the new warehouse operations center is given in the control room simulator 2.0, the unique ‘room of the future’. This is where experts from the logistics sector come together to discover JST’s strategies and integrated models. Visitors test ergonomic furniture and take control of the video walls themselves. Whether in a virtual meeting or live on site: During the workshop, the project, objectives and budget are customised and defined.

This is followed by on-site discussions and web meetings during the planning phase. Photorealistic 3D images and film trailers help with the decision-making process. Climate, acoustics and lighting are also part of the JST control room team’s “all-round carefree package”.

Project workshop in the control room simulator

Project workshop in the control room simulator

A look at our projects: Breaking new ground in logistics with JST know-how

Almost three decades of control room expertise – that’s what we stand for! With hundreds of great projects. JST installations – these are warehouse operations centers, control stations for logistics and control rooms for intralogistics. They are responsible for transport monitoring, warehouse control, management systems, optimisation of warehouse processes and much more. Automation in intralogistics and digitalized material flow control are among the many challenges facing the industry.

Fast and productive thanks to standardised user interface

Precise control of processes and high productivity are achieved in the warehouse control center through central monitoring of logistics tasks. Premise: The control center team has access to a handling option that bundles all relevant sources. The myGUI® operating platform from JST fulfils this requirement. The interactive 3D interface mirrors the control room architecture and ensures a holistic view on the logistics chain.

With the KVM solutions JST MultiStreaming® and MultiConsoling®, all systems can be controlled with just a single mouse/keyboard unit or optionally with the JST CommandPad®. Switching workstations is a thing of the past. All applications are summarised in one view – system-independent, intuitive and convenient!

More about myGUI® and JST CommandPad®

More about myGUI® and JST CommandPad®

PixelDetection®: a keen eye for faults and deviations

Error-free data acquisition, reliable accuracy and high quality – fast reactions to early warnings and alarms are necessary for a warehouse control center to fulfil these requirements. JST’s PixelDetection® software – also known as ‘the operator’s eye’ – monitors all relevant logistics processes in real time and recognises critical events immediately. The tool scans patterns in the background and “sorts” deviations into predefined escalation levels.

Thanks to pre-set intelligent filter and analysis functions, only relevant alerts are sent. Operator ‘alarm fatigue’ can be avoided. Depending on the alarm prioritisation, notification chains or automated measures such as repeat orders or maintenance requests can also be triggered.

Software relieves the operator team

Software relieves the operator team

A head start with JST components: Modern tools and systems reduce stress and response times

Constantly analyse material flow and inventory. Identify risks. Respond quickly and efficiently to alarms and initiate the necessary measures. When monitoring logistics processes, employees have to make decisions and deal with critical situations in the shortest possible time. After all, interruptions to intralogistics processes can have serious economic consequences. Centralised real-time monitoring supports the team in the warehouse control center on the basis of automated processes. Modern tools and systems reduce the stress level for the operator. Ergonomic components provide additional relief.

Effective sound absorber with alarm function: OPAL X11®

This practical solution measurably reduces noise pollution caused by sound: the acoustic ceiling sail OPAL X11® not only acts as an effective sound absorber in the control center. It also optimizes lighting during shift work and can be used as a source for audiovisual alarms if required.

When alarms seem to magically switch on

Computers and cameras that switch on automatically as if by magic in the event of an alarm? In combination with special interfaces, the DisplayWalls from JST make such event-controlled scenarios possible. Another advantage: the entire team is alerted at the same time. No alarm is lost!

Right of way for safety with innovative software from JST

We pay the utmost attention to the topic of “security”. Based on nearly 30 years of experience, JST has developed software solutions that enable automatic, event-controlled alarm functions (PixelDetection®) on the one hand and convenient login and logout via chip card (myLogin®) on the other.

Reduce stress for employees in the logistics control station

Efficient, safe and convenient! With JST MultiStreaming® it is possible to significantly reduce stress factors in the control center. Switch any source to any desired monitor, only one mouse and keyboard per workstation, better climate thanks to outsourced hardware are just some of the advantages.

Simplified handling for all sources in the control center

A user interface in which the control center operators can easily find their way around. An interface that reflects the operator’s own control room as a 3D layout. On this basis, the JST developers have designed myGUI®, a platform that offers simplified access to the handling of all systems.

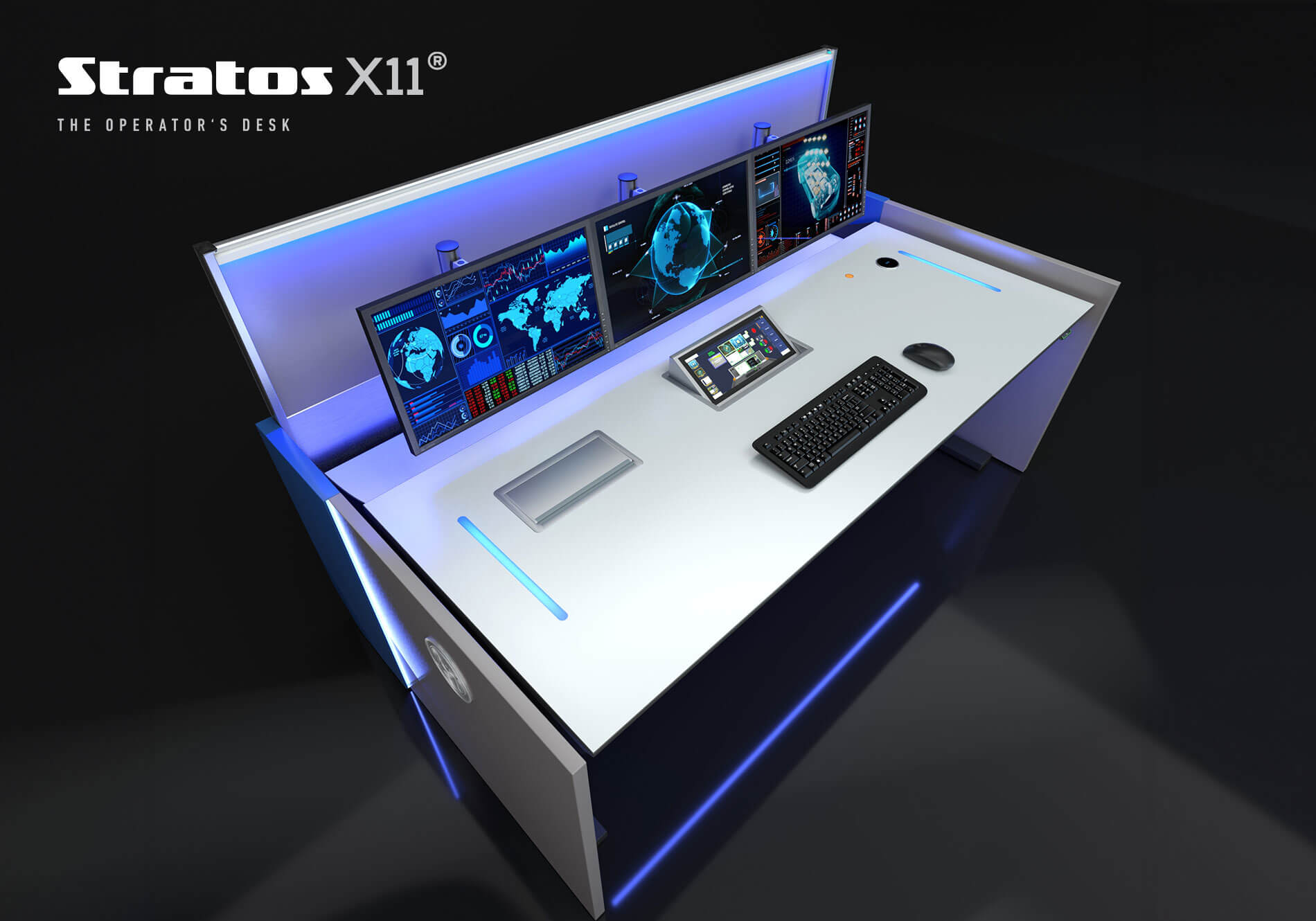

More ergonomics and comfort especially for shift work

Ergonomics is one of the key requirements in 24/7 mode within the control room branch. In the central logistics operations center, high levels of responsibility and pressure to make decisions cause stress. Ergonomic furniture solutions from JST provide a counterpoint. Bestseller: the Stratos X11® console.

Experience more at a planning workshop in the control room simulator

Having visions of the future is good. Experiencing is better! Visit the control room simulator, unique in Europe, where state-of-the-art technology and the latest ergonomic know-how are combined. The control room of the future. The special feature: Here you can touch everything and try it out for yourself.

Whether virtual or live on site – the workshop in the control room simulator is free of charge.

We kindly ask for prior registration.

We offer our customers unique products and solutions for control rooms. An exclusive benefit that only JST can provide.

We have been working in the business for more than 30 years. We would be happy to bring our many years of know-how to your project.

This means that you benefit from our extensive experience and smooth project realisation processes. Because JST keeps everything in mind!

Our experts are among the best. They have been designing control rooms for years. Our team enjoys working together – for you!

What clients say about their experience with JST – Jungmann Systemtechnik®

„PixelDetection® software has allowed us to significantly improve our response time.“

„I can speak for all my colleagues: The control center is a huge step forward for us.“

„Great products, great service and a very friendly team at any time of cooperation.“

This is where visions become reality: JST components pave the way into the digital age

The integrated control room models from Jungmann Systemtechnik set new standards in efficiency and resource management. Innovative components make the control of your company’s strategic and operational core tasks not only more convenient, but also more secure. We are at your side to develop an overall concept for you that meets the requirements of an increasingly automated world.

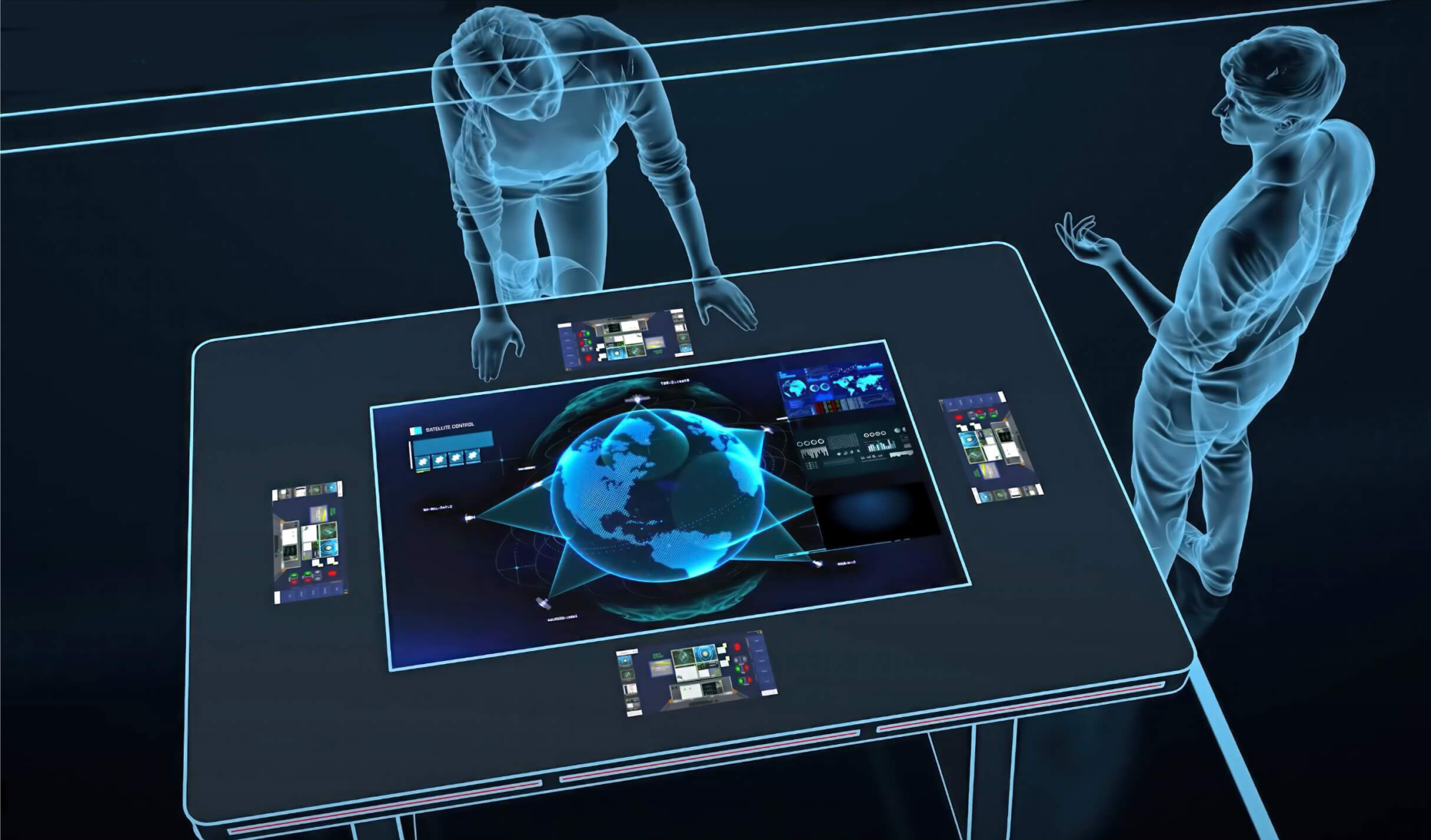

The smart multifunctional table sets new standards

Leading furniture designers have created the AllMedia exclusively for JST. The conference table is far superior to conventional models. The reason: Via JST MultiStreaming®, the system connects the conference room directly to the sources of the control center, which are immediately available.

The right video wall for every room

Monitor walls from Jungmann Systemtechnik adapt exactly to the structural requirements and size of your control room. We offer various options for different needs, ranging from the carrier plate for wall mounting the monitors to mobile DisplayRacks and multifunctional DisplayWalls.

Increased attention in case of events

Whether DisplaySuit, Stratos X11® operator console or OPAL X11® ceiling sails – the integrated AlarmLight changes color depending on the event and thus attracts everyone’s attention. Red or pulsating light gives the control room team a clear signal: “Attention! A reaction is required here!”

JST DisplayWalls – the team players in the control center

Video walls from JST are the basis for a new level of event-oriented surveillance efficiency. Crystal-clear 24/7 displays and the integration of of real-time data pave the way for precise monitoring and fast decision-making. Proactive alarm visualization reduces response times.

Security and convenience go hand in hand

Access-protected and air-conditioned, the control room hardware is housed in the external technology room via extender solutions. Data is transmitted in real time without any loss of quality. An additional benefit: heat and noise pollution are kept away from the control room.

Masterpieces in the control room

Fully integrated operator consoles “made in Germany” impress with their workmanship, design and fulfillment of legal ergonomic requirements. By merging with the hardware and software solutions developed by JST, the Stratos X11® becomes an indispensable command center in the control room.

Interactive, creative, communicative!

A multifunctional situation table as a central hub. The JST TacticTable® is gaining a foothold in the market as a smart information hub for all control room applications. The performance potential and skills of the individual are multiplied by bundling creative concepts and ideas in a team.

IP streaming solution for control room management

Operate any source on any desired screen. Just one mouse and keyboard required for all applications. Intuitive handling with the myGUI® interface. Cost-saving and with a sharpened focus on security. The convenient KVM solution JST MultiStreaming® offers flexibility without limits!

Fixed contact person for all phases of the project

Workflow and task coordination with the specialist departments

Professional implementation of all components

Employee training and initialization of the new Control Center

Turnkey Solutions:

Integrated overall solution creates a real competitive advantage

You want a control center where all information comes together? A control room as a secure basis for the requirements of the digital future, precisely tailored to your processes and needs?

With our experience from more than 600 projects, we are the right partner for turnkey solutions that transform your control room into a profit center.

The right solution for every control center

Ergonomic furniture, video walls, control technology and much more – the JST world offers the entire spectrum of control room equipment. Whether warehouse control station, operations center for logistics or intralogistics: Wherever material flows need to be controlled efficiently, wherever inventory handling and warehouse management are involved, JST supplies suitable and customised concepts. Watch our videos to find out how comprehensive our support is and what modern options for alarm detection with JST look like.