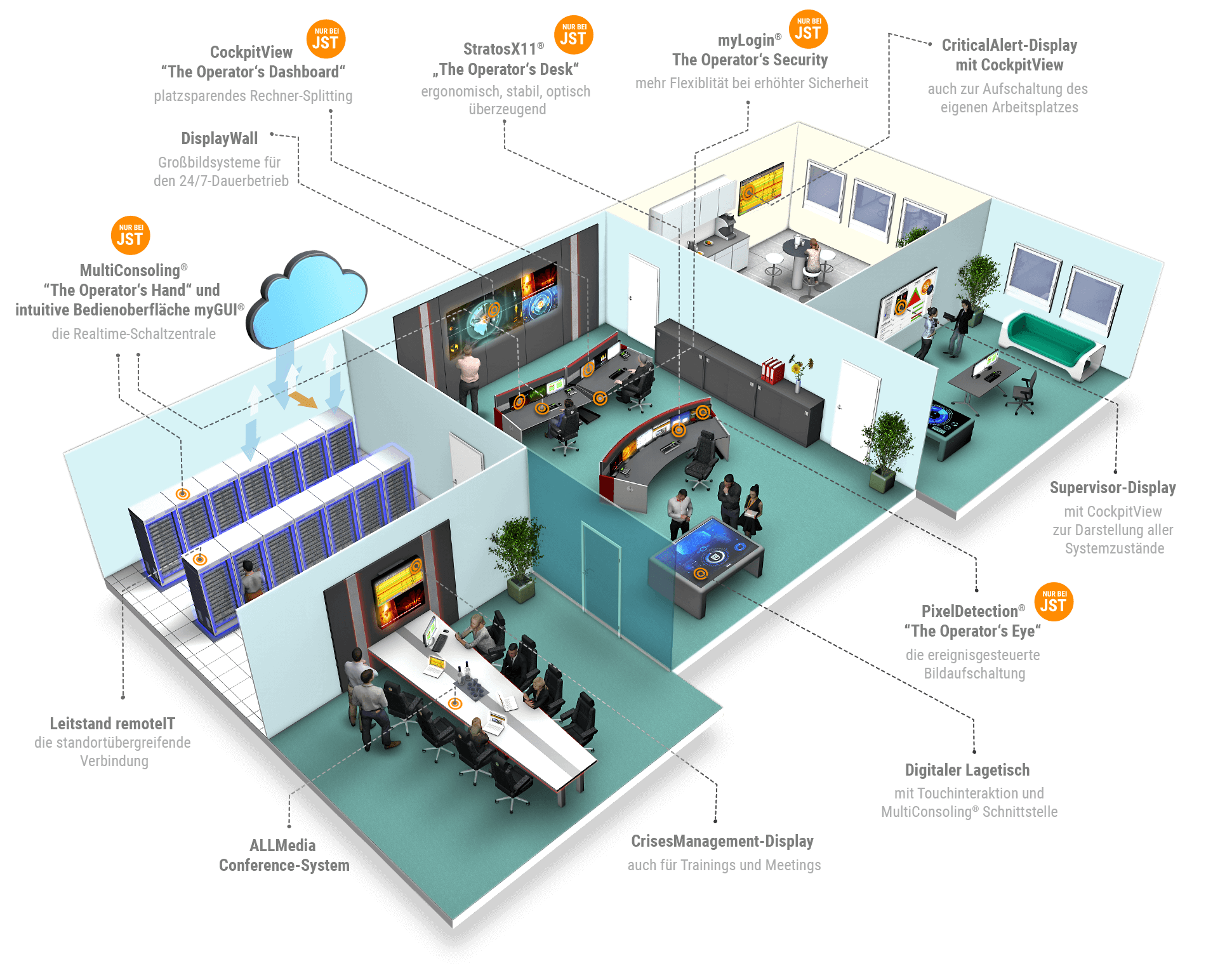

Warehouse control station and control room for logistics

In logistics, the warehouse control center is the central point of the entire warehouse management system.

Industrial companies of all sizes have now recognized that a focus on processes and logistics has become indispensable.

JST Systemtechnik analyses the conditions on site and implements the new logistics control center according to your needs.

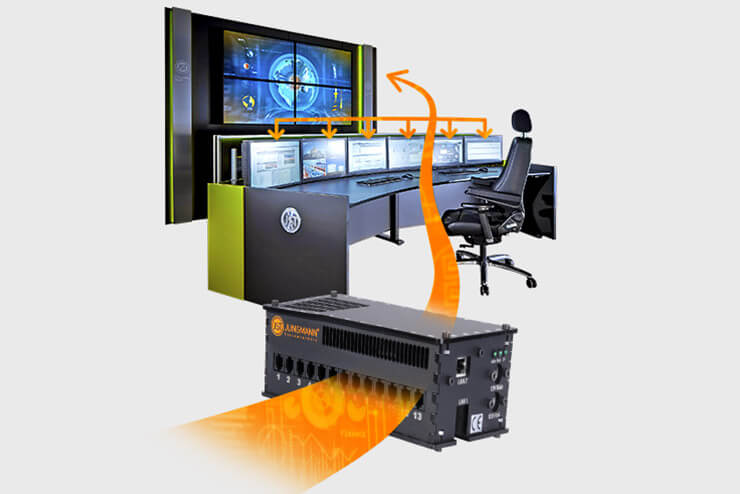

With the innovative ProfiTools such as CockpitView® and the large screen technology from JST the employees have all processes in the warehouse control center perfectly in view 24/7, detect faults and shut them down immediately.

Thanks to digitalization, the employees in the control center for logistics receive more and more information.

Those who use this information correctly can extend their lead in the market.

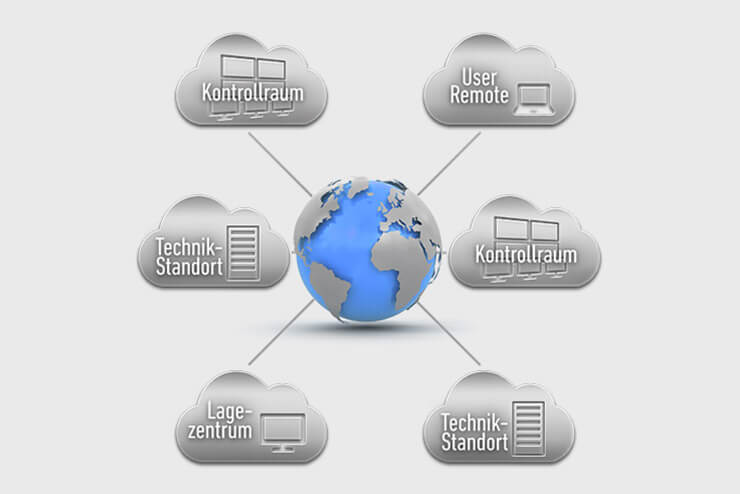

Procurement, production and delivery can thus be efficiently monitored with a MultiConsoling control system.

With our PixelDetection® you keep the overview and receive alarm signals immediately if necessary.

JST brings your logistics safely on the way with the right control center!

-

Visualization of all processes

-

Planning and release of all functions

-

Event monitoring in the inventory control center

-

All alarms immediately visible

-

Fast fault clearance

Chosen by leading companies and institutions

Practical examples: Warehouse control center and control center for logistics

Logistics companies rely on the know-how of JST Jungmann Systemtechnik for the planning and implementation of their control center for logistics.

A modern control center for logistics helps the employees to control the warehouse.

Material flow systems and operating

states are clearly

displayed on monitor walls.

If faults or downtimes occur, they are directly visible.

The employees are also more alert thanks to the ergonomic

control room furniture, they have everything perfectly under control and are able to introduce the required measures for

troubleshooting the problem.

JST knows the demands and knows with which professional

Hardware and Software solutions your warehouse will run like clockwork.

We will be happy to put you in touch with the respective contact person.

Simply everything fits - control center logistics in the distribution center

dm-drogerie markt operates 2,536 stores across Europe and employs more than 39,000 people.

The 25,450 dm employees in Germany generated a turnover of 4.5 billion euros in the financial year 2010/2011.

Group-wide sales exceeded the 6 billion euro mark for the first time.

The current 1,300 dm stores in Germany are supplied with the drugstore range from two national distribution centers in Weilerswist near Cologne and Waghäusel in Baden.

Children’s textiles are picked in the third dm distribution center in Karlsruhe.

Project manager

HARTING with innovative manufacturing cockpit

The need for information in production and transport logistics is constantly increasing.

The demand for data transparency of increasingly complex processes is becoming significantly higher.

The HARTING Technology Group develops, produces and integrates RFID technology.

Hardware, software, system integration and consulting are combined under one roof.

The entire execution of the project (consulting, conceptual design, implementation) was carried out in an excellent manner, quickly and with high quality.

The service offered by JST for ongoing operations also responds promptly and successfully.

Working with JST has been very pleasant and professional at all times".

Project lead

Was möchten Sie als Nächstes tun?

FAQ

What is a control center for logistics?

In logistics, a control center is the heart of the entire shipping system.

The logistics control center helps the employees in the targeted and error-free operational control of the warehouse.

From here the goods are distributed and prepared for transport to the remote business branches.

All operating states of the systems responsible for the material flow are clearly displayed on a central monitor wall in the warehouse control center.

If malfunctions occur during operation, they can be detected directly using the PixelDetection® and the necessary measures for an efficient remedy are initiated immediately.

Anyone who commissions a control center for logistics will be able to achieve a not inconsiderable increase in production and cost reduction in the planning and processing of the material flow.

What are the tasks of the warehouse activity monitor?

In a warehouse control center, the most diverse tasks come together centrally.

From here, the employees of the logistics control center have a clear view of all individual stations.

No deviating from normal operation escapes the operator.

Thanks to our professional software tools such as

PixelDetection® and

CockpitView

errors are immediately reported and quickly detected.

The tasks in the warehouse control centerinclude:

- Controlling

- Planing

- Optimization

- Visualization

- Showing performance limits

- Display of the system status

What is the central point in a warehouse activity monitor?

To ensure that all processes are always in view, the central point in the warehouse control center is the monitor wall.

The SPOC system (Single Point of Control) on the large screen wall allows every employee on duty to see at a glance.

If there is a “bottleneck” or other problem, the causes are quickly identified in the warehouse activity monitor.

The fully automatic control of a logistics system is monitored on the large screen wall over the complete overview, malfunctions are immediately displayed and the support can react immediately.

In addition to the technical components we always pay attention to the most valuable in the whole system: the people on site.

For your employees to do an excellent job, they need the best possible workplace.

Our control room furniture meets the latest ergonomic requirements and supports the good working atmosphere in the control room.

The quite demanding tasks in shift work are supported by our control room consoles and the Recaro operating chair 24/7.

The matching surrounding furniture fulfills both ergonomic and aesthetic aspects with flying colors.

Whether multifunctional conference and meeting tables, functional furniture with integrated sound absorbers or paneling that is worth seeing.

We pay attention not only to outstanding functionality but also to high-quality design.

Why is it important to constantly monitor the warehouse logistics in the warehouse control center?

Warehouse logistics is an important component of corporate logistics and comprises the processes of planning, controlling and monitoring warehouse and transport processes, such as determining the number and scope as well as the function and locations of individual warehouses.

In addition, the tasks of warehouse logistics include receiving materials, checking them for usability and, if necessary, passing them on to the requested item.

The goal of warehouse logistics is the optimized use of warehouse functions.

The background is that all stations are interdependent.

The goods in a warehouse must be traceable at all times, both on the warehouse shelf and in the system.

We will be happy to answer your questions on the subject of warehouse control center and control center for logistics

0800-777 8 666You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information