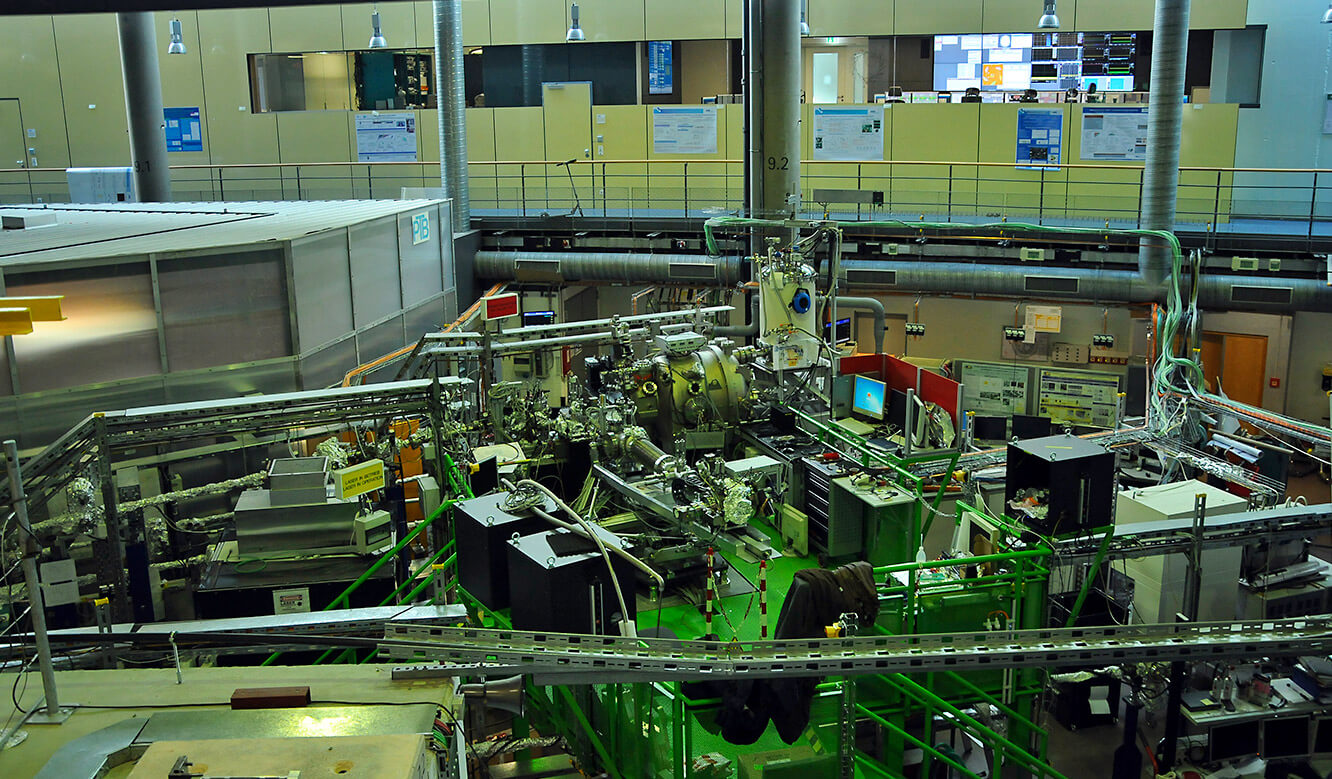

Photo 1 | JST control center concept: A carefully thought-out room concept, functional planning and proactive visualisation of the various systems - At Helmholtz Zentrum Berlin, the operators of the control room benefit from the extensive experience of the JST specialists.

Photo 2 | JST Planning: Each operator has a direct view from his workstation on the status of the electron storage ring "BESSYII" in the radiation protected storage tunnel, which is controlled and monitored from the new control room.

Photo 3 | JST furniture: Optics and design are also very important for Jungmann products. Here is the logo of Helmholtz-Zentrum Berlin on the side walls of the operator desks.

Photo 4 | JST 3-D planning: Offers the customer a preview of the new control room: realistic 3-D planning and design...

Photo 5 | ...and their implementation in the following project.

Photo 6 | JST 3-D planning: Spatial conditions are taken into account in 3-D planning as well as colours and light influences...

Photo 7 | ...so after the realisation the customer is offered a detailed implementation of the previous designs. Here: a perspective that also includes a view into the experimental hall.

Photo 8 | JST Operator Desk: By means of infinitely variable electromotive height adjustment, the worktables can be adapted to the operator's needs; for example, switching between sitting and standing to relieve back strain. Well visible on this illustration: The special deck lighting, which creates optimal conditions for working in control centers.

Photo 9 | JST Ambient Light: As an alternative to the complete lighting of the room, here the same perspective as in the previous motif. The AmbientLight makes it possible to change the working atmosphere at the touch of a button.

Photo 10 | JST Monitors: A curved monitor rail makes it possible to mount monitors in a continuously horizontal position. The tilt and rotation angle can be optimally adjusted for each operator.

Photo 11 | JST large display wall: Perfectly fitted into the sound-absorbing large screen paneling: the eight 46-inch LCD displays. Other practical details have been integrated almost invisibly and can only be guessed at: Valuables compartments for employees, storage space for documentation, integration for technical equipment.

Photo 12 | JST large display wall cladding: Special feature of the wall cladding in the control room of Helmholtz-Zentrum Berlin: drawers were integrated, which serve here for the functional storage of mobile phones for on-call duty.

Photo 13 | JST large display wall cladding: At Helmholtz-Zentrum Berlin, the large display wall panelling not only reduces the noise level in the control room, it also offers additional storage space thanks to its multifunctional equipment with hinged doors and drawers.

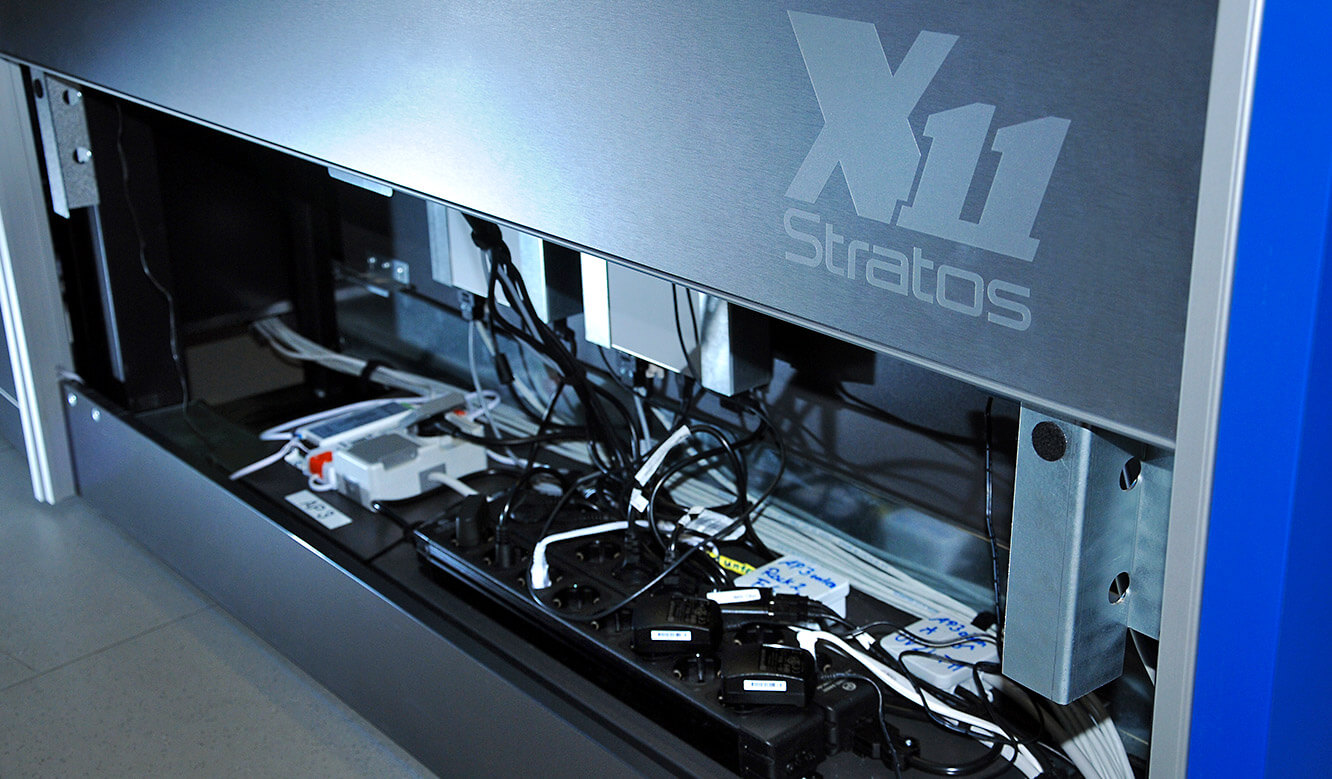

Photo 14 | JST Power Port Data Box: Flush with the surface of the Stratos X11® OperatorDesks: the Power-Port Data Box, which...

Photo 15 | …when open, offers not only LAN, USB and 230V connections, but also a switch for the spotlights distributed in the room.

Photo 16 | JST control center desk: The STRATOS X11® OperatorDesk not only offers decisive advantages in terms of appearance and ergonomics...

Photo 17 | …behind the rear wall cladding there is also generous storage space for large quantities of cables and technology.

Photo 18 | JST MultiConsoling®: With the myGUI user interface the large display wall starts at the workstation. With MultiConsoling®, not only are large display walls controlled, but the monitors at the workplace are also switched with all signals (keyboard/mouse/monitor/audio) in real time.

Photo 19 | JST technology: Impairments due to heat or fan noise are not an issue in HZB. In connection with the JST MultiConsoling®, all computers were moved to an adjacent technical room.

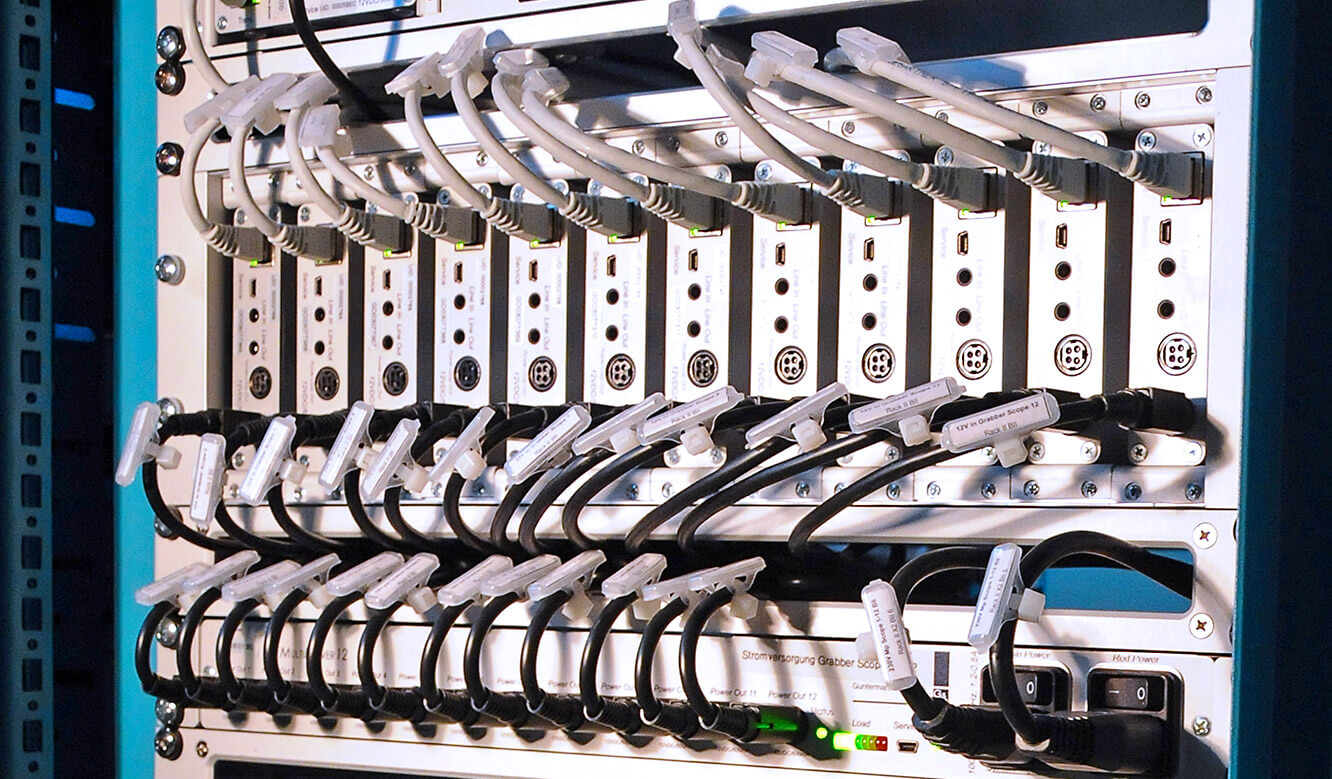

Photo 20 | JST MultiConsoling®: Several MultiCenter are in use in Berlin. On the right: the JST Application Server, the myGUI host for operating the MultiConsoling® system.

Photo 21 | JST technology: In the upper half of the picture are the so-called "grabbers" to which the individual computers are connected. In the lower half of the picture: The grabbers are connected to the power supply unit in a clear and space-saving way.

Plant control room with completely new quality

A control room that not only meets the highest technical and ergonomic requirements, but is increasingly becoming a showpiece: At Helmholtz-Zentrum Berlin (HZB), an outdated, historically grown control room was replaced by a completely new installation from JST – Jungmann Systemtechnik®. “For us, a completely new operating quality has been created here”, comments Ingo Müller, Control System Engineer, on the demanding result.

Control room before and after modernisation

The HZB project team became aware of JST – Jungmann Systemtechnik through a trade fair appearance. From there it was only a small step to the visit in the control room simulator of JST. Ingo Müller: “We were delighted with the possibilities that were offered there and knew: That’s what we want – it fits perfectly into our concept”.

For the two control rooms BESSY II and MLS, the JST professionals visualised exactly this concept, consisting of control center furniture, MultiConsoling® and proactive large-screen technology as “Single Point of Control”, then by means of extensive planning and an entertaining film trailer.

Two storage ring facilities are now monitored centrally in the new control room via state-of-the-art proactive large-screen systems. The greatest profit in the eyes of Ingo Müller: Graphically prepared information about the respective machine status is displayed, at the same time measured signals can be permanently visualised. “The large display wall gives us ideal opportunities we never had before.”

Another completely new aspect for the staff of Helmholtz-Zentrum Berlin is the interest of high-ranking visitor groups. Thanks to the sophisticated equipment from the JST portfolio, the new control room is increasingly becoming a calling card for HZB. In addition to the technical optimisations through large-screen technology and JST MultiConsoling®, the rooms offer ideal climatic and acoustic working conditions. In addition, the control center furniture with ergonomically designed products of the STRATOS X11® series and additional lighting from the JST Ambient Light meets maximum visual requirements.

“Although we have deliberately created a businesslike working atmosphere here, you can see a wow-effect in everyone who opens the door for the first time,” says team leader Ingo Müller happily. He has nothing but positive words for the cooperation with the JST specialists: “The cooperation was positive throughout. Everything worked smoothly and very quickly.”

Project Report "Helmholtz-Zentrum Berlin"

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationPlanning of the turnkey control center

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationTime lapse during the installation

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationMore about Helmholtz-Zentrum Berlin

As one of 18 centers of the Helmholtz Association, HZB operates the neutron source BER II and the electron storage ring BESSY II, both of which are available with the highest reliability to an international user community for research purposes and provide deep insights into the structure of materials and the processes taking place in them. An important research focus at HZB is materials research with a focus on energy research, especially thin-film photovoltaics and materials for the conversion of solar energy into hydrogen (solar fuels). Around 1150 people are currently employed at the two locations Berlin-Wannsee and Berlin-Adlershof.

Unsere Referenzen heute (Auswahl)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner Zement, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)