Operation Center ensures smooth airport operations

Without them, even the largest and strongest “birds” are condemned to a virtual standstill, to motionlessness. We are talking about the employees of EFM (de-icing and aircraft towing at Munich Airport) GmbH. The team of the subsidiary of Lufthansa and Munich Airport ensures that air traffic runs smoothly and that all aircraft are available at the desired positions. This is made possible by the coordination activities of the control center, the so-called Operation Center, where the control room crew finds ideal conditions for their work thanks to state-of-the-art technology and ergonomic furniture from JST – Jungmann Systemtechnik®.

What significance the EOC (EFM Operation Center) actually possesses, becomes quickly clear if you realize that an aircraft does not have a reverse gear. A huge Airbus 380 lands there, the passengers get out, and now the plane has to be brought from its parking position to a hangar, for example. This requires so-called pushback and subsequent towing operations.

Munich Airport Operation Center before and after modernization

Punctuality at the airport is the top priority

If the 140 or so tractor drivers and de-icers were not working around the clock to carry out these shunting movements, nothing would be possible at a large airport like Munich within a very short time. The delay rate would rise rapidly.

The control center is responsible for operating around 200,000 shunting operations and 15,000 de-icing operations per year, ensuring that everything runs smoothly at the airport in the Bavarian state capital and that the planes can take off on time.

Trouble-free service with suitable control center technology

An important prerequisite for this trouble-free service: a control center that offers the perfect basis in terms of technology and ergonomics.

For years, Florian Hilz (consultant to the EFM management) and his team had been convinced: “We wanted to realize our new control room with JST”. As part of a move to a new building, the right moment had come to implement these plans.

"Visits and expert advice were great!”

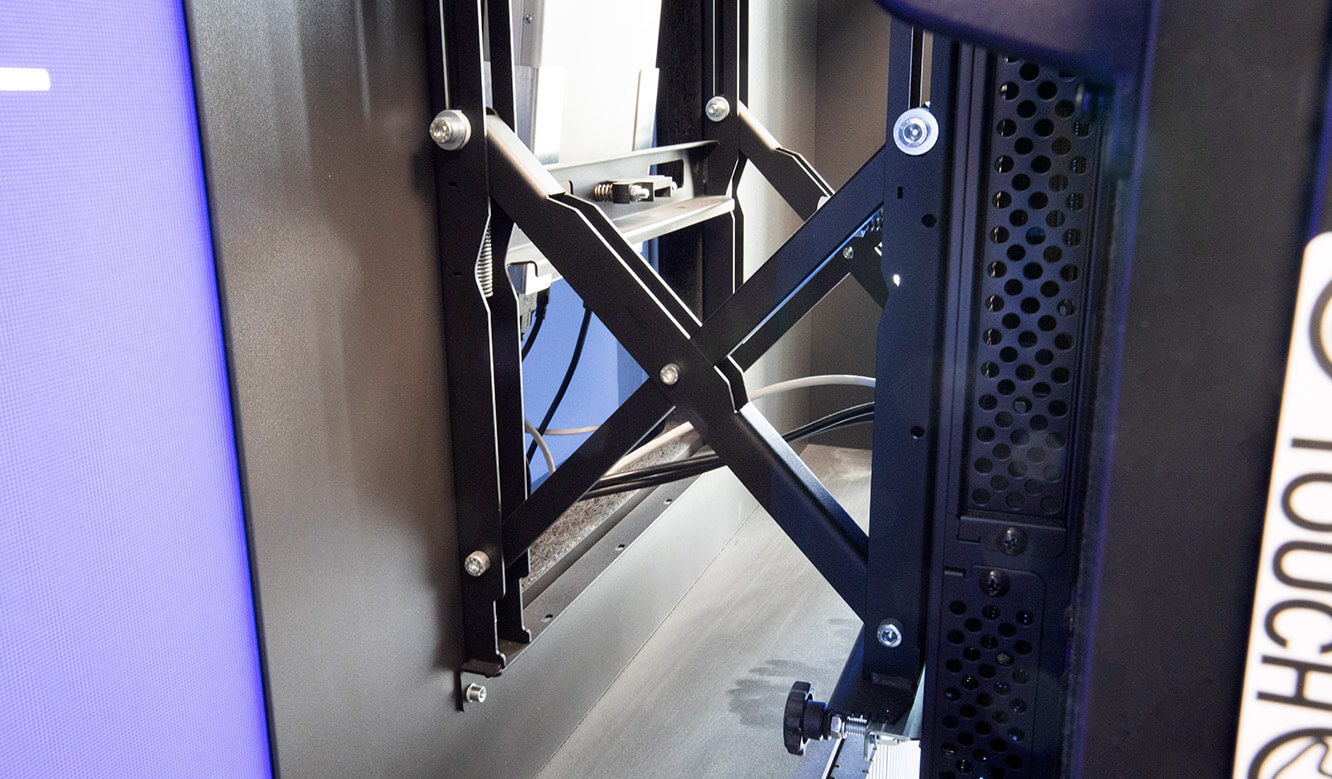

No more confusing displays consisting of eight monitors per workplace, with poor lighting and poor ergonomics. Project Manager Florian Hilz did not only have a look around in advance in the other Jungmann control rooms that have already been implemented at Munich Airport, he also visited the JST control room simulator together with his team. “The visit and the expert advice were great – one of the biggest decision factors for us,” the expert recalls.

Control room concept impresses in all disciplines

If you ask Florian Hilz today what has improved with the JST control room compared to the past, he gives a concise and meaningful answer: “Everything”! Thanks to the proactive video wall and the flexible MultiConsoling® control technology, the number of monitors at the workstation has been reduced to three, operated with only one mouse and keyboard. A cleverly designed lighting concept, the avoidance of noise and heat emissions through computer relocating to an external technical room, individual software solutions and, last but not least, ergonomic furniture are further factors that make the wish for the perfect control room a reality. For Florian Hilz, the best confirmation that he has found the right partner in JST is the feedback he receives: “Every one of our employees is enthusiastic. Even the visitors who enter the Operation Center are impressed. Whenever guests from the airport or Lufthansa come to us, the motto is always ‘This will be the new standard at Munich Airport'”. His conclusion: “We couldn’t have done it any better.”

Press review

Our references today (selection)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)