Control center as the heart of the waste treatment plant

All operating and emission data converge at their premises, they check that the limit values are not exceeded under any circumstances, thus guaranteeing the highest safety standards: The operators in the new control center of the Müllverwertungsanlage Bonn GmbH (MVA), a subsidiary of Stadtwerke Bonn, monitor all data and functions at the heart of the plant. This important task is supported by products from JST – Jungmann Systemtechnik®.

More than 1,000 tons of waste arrive at the waste treatment plant every working day. Every year, more than 500,000 megawatt hours of steam are generated from the delivered residual waste – enough energy for a small town. In order to guarantee operation of the waste treatment plant 365 days a year, around the clock, according to the highest safety standards, the persons in charge had the most modern control technology from Jungmann Systemtechnik installed.

The suitable switching technology was needed

The background to the new construction of the central control center was the extension of the plant by a new waste bunker. “In this context, we wanted to integrate the workplace of the crane operator, who controls the crane system, into the new control center,” explains Frank Nachtsheim, plant manager at MVA. In future, it should be possible for the operators in the control center, which is manned 24/7, to take over the task of the crane operator – with the appropriate environmental technology.

MultiConsoling® as an ideal solution

This is exactly where JST’s MultiConsoling® concept comes into play. Frank Nachtsheim: “We didn’t have to install any additional monitors and mouse/keyboard units, but can conveniently switch on all desired applications by key combination. That was part of the charm for us”.

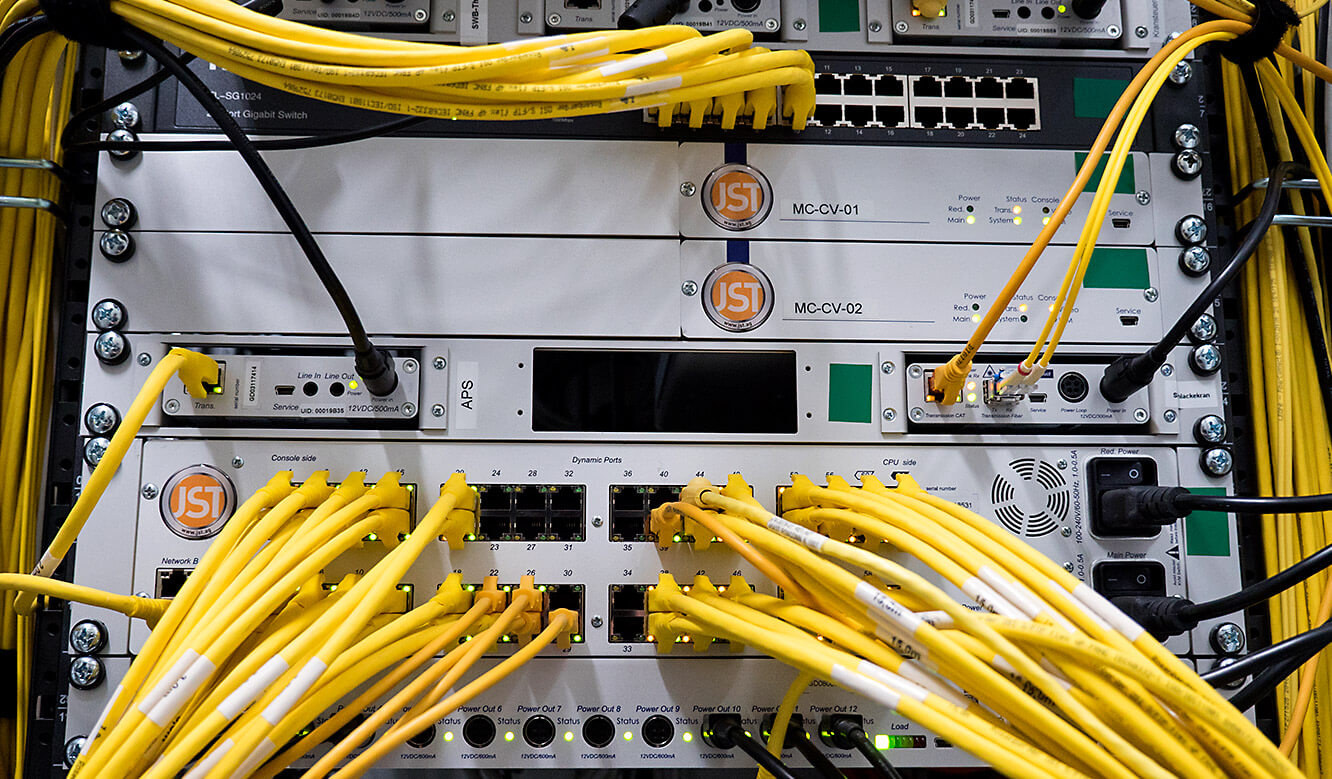

ST MultiConsoling®: The myGUI – shown here on the left screen – serves as the user interface for the JST MultiConsoling®. Advantage of this technology: Computer signals with keyboard, video, mouse, audio signals, cameras and even TVs are flexibly displayed in real time on the monitors at the workplace or on the large display walls.

Technical University recommends Jungmann

But there was another convincing reason for commissioning JST to equip the new control center: in order to harmonise all the wishes for the new control center, the waste treatment plant project team commissioned an exposé from the Technical University of Dresden which included lighting, colour scheme and, most importantly ergonomic issues. In this paper, the TU Dresden already referred directly to the expertise of the Jungmann specialists.

Ergonomics and technology perfectly matched

“Then it was clear to us that we should seek contact with JST,” says Frank Nachtsheim. The result of this cooperation is not only a perfectly coordinated technical concept, the PixelDetection® alarm software. Ergonomic control center desks are also part of the equipment The advanced control center is complemented by a large-display system with 8x 46 inch slimline displays, which contribute to the safety of the entire plant through emission and process monitoring.

JST Operator Desk: The stepless electromotive height adjustment makes it possible – the specialStratos X11® CommandDesks can be individually adapted to the needs of every operator. For example, to relieve back strain, the user can switch between sitting and standing.

JST monitor articulated arms: The workstation monitors are attached to the OperatorDesks with height-adjustable 3D articulated arms. They allow an optimal and individually adjustable viewing angle and viewing distance on all displays through a parabolic arrangement.

Contact is intensified on the ko:mon

But with the completed installation and successful operation of the new central control center, contact with Jungmann Systemtechnik is far from over for the experts from the Bonn treatment plant: As early as September, three employees of the plant will visit the ko:mon-Kongress in Bremen in order to seek a direct exchange of experience with other industry insiders. Frank Nachtsheim: “A good way to stay up to date with the technical side of things.”

Our references today (selection)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)