Photo 1 | JST control room: Quality not quantity! The view through the porthole gives a first impression of the new control room that controls the electron storage ring Metrology Light Source, a particle accelerator whose radiation is used in industry and science.

Photo 2 | JST control room planning: Convenient, efficient and ergonomic - thanks to close planning coordination and individual adjustments, the ambitious project in Berlin was realized. The control room of the Physikalisch-Technische Bundesanstalt is directly connected to the world-famous "BESSY II" control room of the Helmholtz Center.

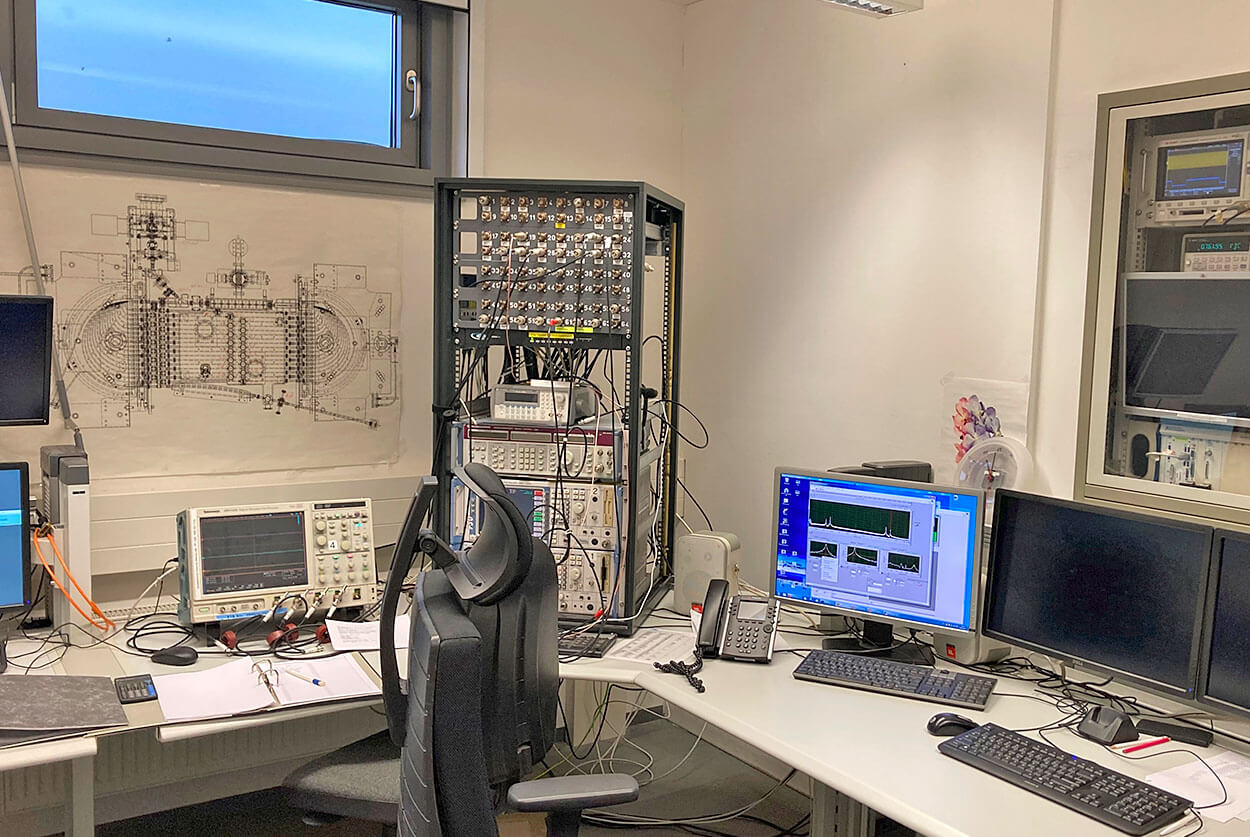

Photo 3 | Before: The former control station in the PTB building had more of a laboratory character. "Many cables, many stickers, some things no longer even in operation - and due to constant expansions, no longer intuitively operable," describes project manager Ingo Müller. His conclusion: "It was simply a matter of tidying things up."

Photo 4 | After: The same perspective, a completely new room. Intuitive handling and a clear arrangement of all components enable efficient and safe control of the plant.

Photo 5 | JST control room furniture: Just one of many details supporting the convincing visual design of the control room in the national metrology institute of the Federal Republic of Germany: Corporate Design elements, such as the PTB (Physikalisch-Technische Bundesanstalt) logo.

Photo 6 | JST furnishings: Height-adjustable control room desks and acoustic ceiling sails, which have a positive effect on the influence of light and sound, set new standards not only ergonomically, but also visually.

Photo 7 | JST control room consoles: Embedded directly into the surface of the Stratos X11® consoles are QI charging pads that make it possible to conveniently charge mobile devices - wireless charging!

Photo 8 | JST control room furniture: One of the many special features of the control room bestseller Stratos X11®: the brush head seal, visible here in the upper image area. This feature makes it possible to neatly route cables when using the electromotive height adjustment. Also visible in this motif is the Power-PortData pull-out...

Photo 9 | ...a solution with which all desired connections are available directly at the operator's workstation.

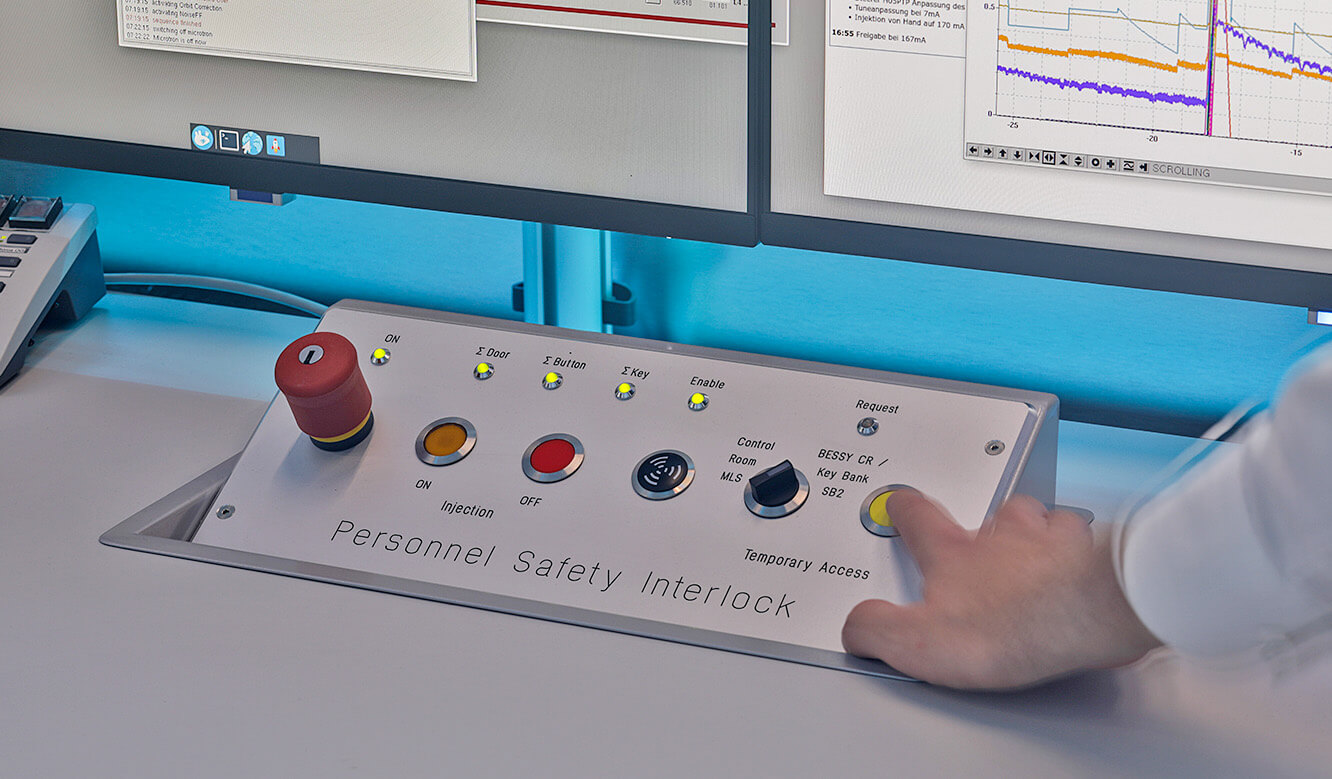

Photo 10 | JST control room planning: Special equipment element in the PTB control room: The storage ring is located in a shielded bunker due to the hazard of radiation. To ensure that there is no risk to employees, a manual "Personnel Safety Interlock" was constructed with mechanical switches that can be accessed from the control station without delay.

Photo 11 | JST CommandPad®: JST CommandPad®: Same look as on the picture before, however anything but "mechanical". One tap on the JST CommandPad® is all it takes to safely operate the control station applications.

Photo 12 | JST air quality sensor: Due to the limited room size, an indispensable tool for the MLS control room - the air quality sensor. Ingo Müller: "This is particularly interesting when there are several people in the room; it allows us to check the oxygen content and dust load."

Photo 13 | JST Stratos control room consoles: The Stratos X11® consoles are equipped with the JST AlarmLight. Alarming deviations of the measured values can be visualized with red light, for example.

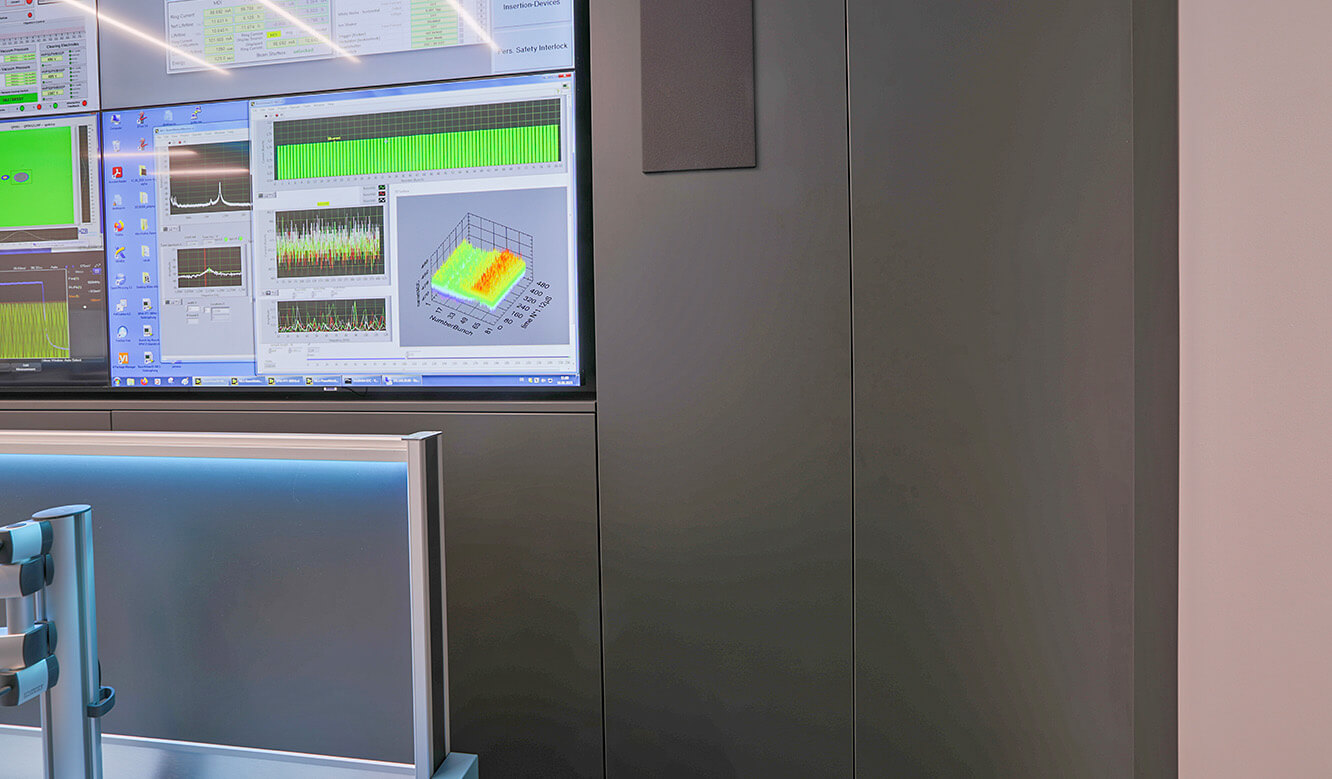

Photo 14 | JST Videowall: All-rounder with many functions: The cover of the JST DisplayWall not only visually creates the appropriate frame for the large-screen displays of the Videowall. Among other things, the speakers for the acoustic audio warning system are integrated here. In addition, it was possible to realize a room-in-room concept behind the wall, which offers sufficient space for the complete technical hardware of the control station. This keeps heat and noise away from the control room.

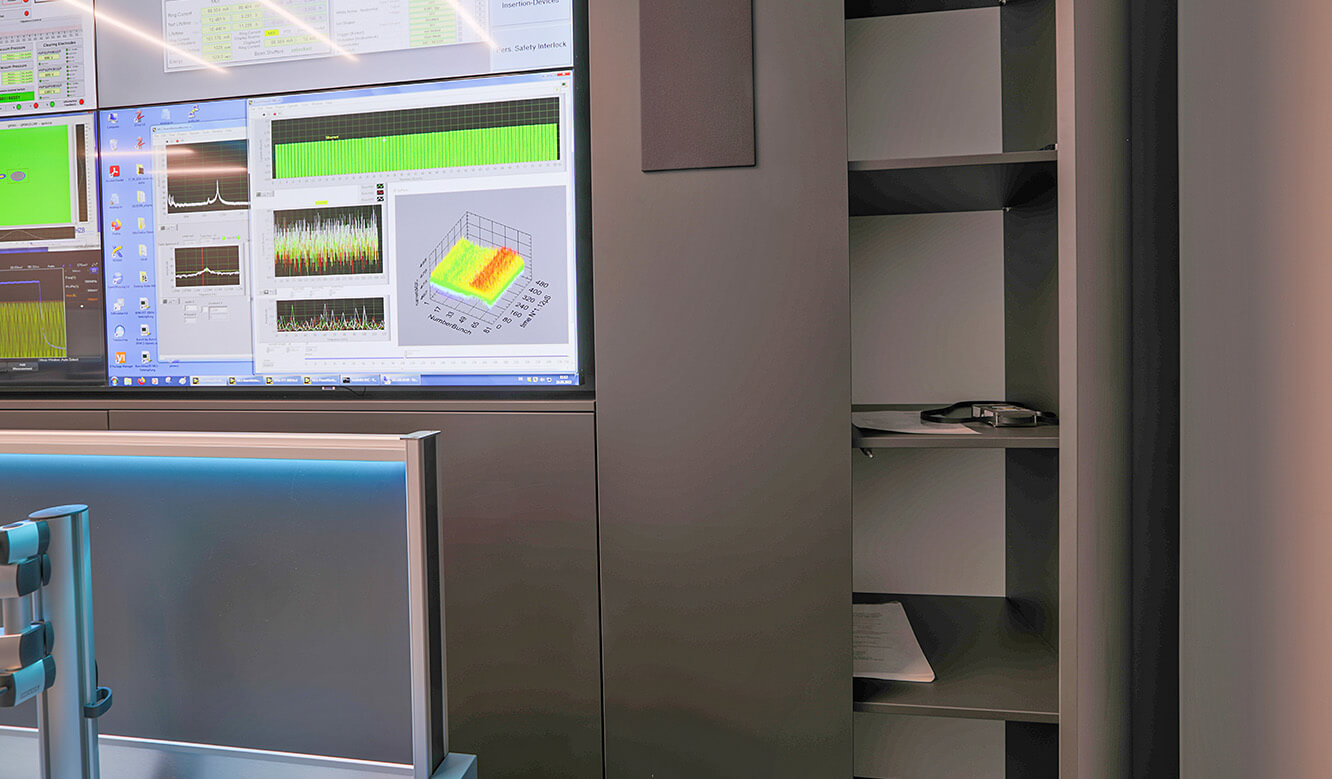

Photo 15 | JST Control Room Solutions: Hardly visible from the outside: The multifunctional DisplayWall offers additional storage space for various materials.

Synchrotron radiation: The "success story" continues!

What do measurements on Mars have to do with the German capital? How can an action in Berlin influence processes on the red planet – hundreds of millions of kilometers away? The answer is found at the Physikalisch-Technische Bundesanstalt Berlin (PTB). The synchrotron storage ring Metrology Light Source (MLS) is used, for example, to calibrate sensors of the famous remote-controlled Mars rovers. The necessary technical equipment to monitor and control these high-precision applications was supplied by JST – Jungmann Systemtechnik®. A new control room offers the scientific staff not only ergonomically best conditions for the extensive tasks, but also an innovative control system.

The resonant name “BESSY II” has gained worldwide recognition over the past decade. Researchers from Germany and abroad, the Who’s Who from business and politics, even the former chancellor – they have all been able to convince themselves of the potential applications of the electron storage ring in the JST control room at the Berlin Helmholtz Center. The MLS system of the neighboring Federal Institute is also controlled from the BESSY control center. A supplementary control station on the PTB site is used additionally, in the case of lengthy series of experiments, for example. Researchers and specialist groups benefit from the synergy effects of both facilities.

“It was simply a matter of tidying things up”

As Operations Manager responsible for control center management, Ingo Müller is well aware of the background: “The PTB is a close cooperation partner that enjoys a high status in our institution.” However, since the so-called MLS control station had more of a laboratory character, had grown historically and was correspondingly confusing, the desire for an upgrade arose. “It was simply a matter of tidying things up”, says Ingo Müller, who had already implemented the “BESSY control room” project together with Jungmann Systemtechnik. His summary: “That not only went well, it’s a huge success story – to this day!”

PTB control room before and after renovation

Two control center are connected with each other

Against this background, the renewed cooperation with JST was obvious. “We didn’t want to establish a second system. The existing system had to be expanded, so to speak. The two control rooms should be able to communicate with each other; after all, they are connected. In addition, it was important to me to work with JST again because of the good experience,” explains Ingo Müller.

Geo redundancy and a "little spatial miracle"

Whether space probes, detectors for industrial customers or metrological research – with the new monitoring center for the MLS facility, a separate, high-quality installation with geo-redundancy was created for the scientists of the Berlin institute. At the same time, “a little spatial miracle” could be realized here: Physicists monitor many thousands of parameters of the storage ring in just 18 square meters.

A whole control room world on 18 square meters

In addition to the flexible KVM technology MultiConsoling® and intuitive operation via the myGUI® interface, the scientists also have a modern video wall and ergonomic control station consoles at their disposal. The innovative OPAL X11® acoustic ceiling sail is also part of the new equipment, as are integrated QI charging zones in the console surfaces and an AI-supported air sensor that issues a warning message directly via the user interface if limit values are exceeded.

"With combined forces and know-how made possible"

For Ingo Müller, one thing is certain: “The installation is a complete success and has been very well received. Everything is easy to operate, the ergonomics are right and the room has a good atmosphere.” Looking back, he assesses the individual development phases of the MLS installation: “The special achievement was essentially the preparation and planning to use a difficult room efficiently and optimally. In joint appointments on site, we made the whole thing possible with combined forces and know-how.”

Unsere Referenzen heute (Auswahl)

A

B

C

E

H

I

M

N

P

R

S

- s.Oliver, Rottendorf

- SachsenEnergie, Dresden

- SAG, Berlin

- SAG, Nürnberg / Nürnberg Messe

- Salzgitter Flachstahl

- Senvion SE, Osterrönfeld

- SGL Carbon Group, Bonn

- SIEMENS

- SIEMENS, Wegberg

- Spenner Zement, Erwitte

- Städtische Werke Magdeburg

- Stadtwerke Gießen

- Stadtwerke Ratingen

- Stadtwerke Schwerin, Kraftwerk Süd

- Stadtwerke Steinburg GmbH, Itzehoe

- Stadtwerke Wolfenbüttel

- Starlim Sterner, Marchtrenk

- STORAG ETZEL, Friedeburg

- Straßenverkehrsamt Frankfurt am Main

V

Unsere Referenzen (Archive)