Measuring control room: guarantor for safety in industrial processes

Control rooms for chemical and process industries are the central element for live monitoring and smart control of critical processes in modern industrial companies. Efficiency and reliability are top priorities. Key criteria include real-time plant monitoring and compliance with the highest safety standards. Regulatory requirements for the control of systems, machines and processes must be consistently adhered to in order to ensure operational safety in the long term. JST has been successfully planning and implementing integrated complete solutions for control rooms in the industrial sector for decades.

Innovative technologies increase operational safety

Increasing process automation has been confronting control rooms in the chemical, raw materials and process industries with a constant stream of new challenges for years. Many systems work with flammable, toxic or explosive substances. Leaks, overpressure or excessive temperatures can lead to serious accidents. Modern technologies with intuitive human-machine interfaces make monitoring and control easier. However, the integration of existing infrastructures and legacy systems into innovative solutions may prove to be an obstacle.

To avoid misjudgements, experts recommend a standardised user interface. Ideal partner in the measuring control room: the myGUI® platform in combination with the KVM systems JST MultiStreaming® or MultiConsoling®. In addition, video wall technology and ergonomic furniture provide further optimisation.

The operator has access to all sources in the control room with just one mouse/keyboard unit. All processes in the industrial control center are clearly displayed and monitored on a proactively operable video wall. In the background, alarm software detects undesirable deviations. Delayed reactions are a thing of the past. Faults within the processes are recognised and eliminated more quickly.

The convincing before-and-after comparison shows: The control room of STORAG ETZEL Service GmbH is now technically and visually “state of the art”. The control room manages the injection and extraction of natural gas and crude oil at the Etzel cavern facility in East Frisia. Seamless monitoring, early fault detection and efficient process control are among the most important tasks on site.

Control over critical processes – every argument a real “ace up the sleeve”

Secure, fast handling – just one mouse & keyboard for all sources

Efficient, confident access – with a standardised user interface

Automated processes – reducing manual intervention speeds up workflows

Visualisation of critical operating data – on modern video walls

Early fault detection – based on proactive alarm software

The control room for power plants stands for the highest safety standards. There is no compromise on quality and safety in the process industry either. AI-supported analyses and automation can provide valuable solutions to meet these requirements. Condition: A clear user interface summarises new technologies and older control systems in such a way that they can be accessed quickly.

The intuitive myGUI® from JST already fulfils this task with excellence in hundreds of control centers! The platform interface reflects the operator’s workplace as a customised 3D graphic. Simply select a source and place the pre-defined icon on the desired screen using drag & drop. Access in a matter of seconds significantly reduces the reaction times.

Standstill does not exist in the process industry. Sensor technology and analysis functions are becoming more and more precise. Compliance with legal requirements must be fully documented. The importance of energy management is growing. The increasing amount of data requires ever new, smart products to cope with the flood of information. Control and operating systems in the measuring control room must make all this manageable for the operator team.

With the KVM solutions JST MultiStreaming® and MultiConsoling®, reliable and high-performance technologies are available; once hardware-based, once as an IP streaming variant. Both options provide secure and fast access to all control center sources with just one mouse/keyboard unit.

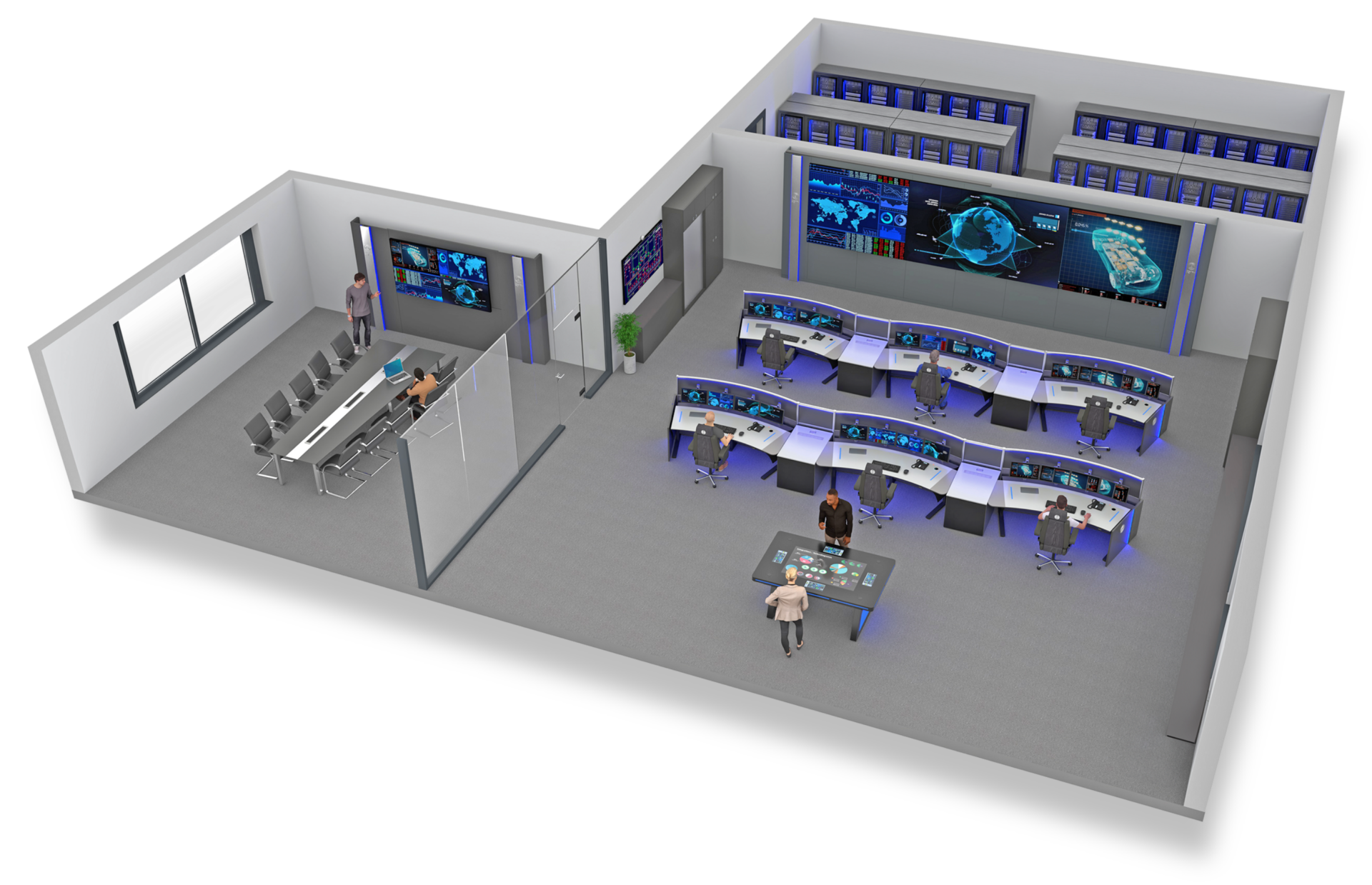

The starting signal for the new warehouse operations center is given in the control room simulator 2.0, the unique ‘room of the future’. This is where experts from the logistics sector come together to discover JST’s strategies and integrated models. Visitors test ergonomic furniture and take control of the video walls themselves. Whether in a virtual meeting or live on site: During the workshop, the project, objectives and budget are customised and defined.

This is followed by on-site discussions and web meetings during the planning phase. Photorealistic 3D images and film trailers help with the decision-making process. Climate, acoustics and lighting are also part of the JST control room team’s “all-round carefree package”.

A look at our projects: When precision and reliability are a question of safety

Almost three decades of control room expertise – that’s what JST – Jungmann Systemtechnik® stands for! With hundreds of outstanding projects. JST installations – these are control rooms in the chemical and process industries, for the energy sector, in power stations, refineries and in raw materials handling. JST control rooms are used wherever critical processes are monitored and controlled. Get a first impression of what it means to work with the leading control room specialists in our photo gallery.

Image 1 | In the central control room of INGAVER (Innovative Gasverwertungs-GmbH) at the Bremen site, the operator team organises and manages all energy media at the site. These include electricity, water, technical gases and compressed air. Modern energy management and process automation are two important elements of the control center.

Image 2 | At BASF in Schwarzheide, a modern gas and steam turbine power plant for the chemical company is monitored and controlled with a KVM system from JST. The Jungmann experts are also responsible for planning, furnishing and the entire equipment with technology and large-screen visualisation.

Image 3 | Here, the control room specialists from JST have implemented a completely new control center for optimum management of the entire plant supply. Precise monitoring and visualisation of critical operating data are among the requirements that the Penzberg plant of the pharmaceutical and diagnostics group Roche placed on Jungmann Systemtechnik.

Image 4 | An extraordinary measuring control room and an ambitious project: the Metrology Light Source (MLS) synchrotron storage ring is used, for example, to calibrate sensors on the famous, remote-controlled Mars rovers. The Physikalisch-Technische Bundesanstalt Berlin (PTB) uses video wall technology to visualise operating data and efficiently control processes.

Image 5 | With the new measuring control room, HeidelbergMaterials wants to create the conditions for CO2 neutrality in cement production at the Geseke cement plant by 2029. The JST components serve as the basis for realising this project. This includes real-time monitoring of critical systems, flexible monitoring and control of all steps in the production and manufacturing process as well as monitoring compliance with the highest standards.

Image 6 | A high degree of automation for AI-supported energy and contracting solutions – this is GETEC Switzerland‘s goal with the new Smart Control Center at the Muttenz Industrial Park near Basel. Performance and scalability are among the benefits of the new control room, which GETEC uses to deliver economically efficient and sustainable energy solutions for the chemical and pharmaceutical companies based there.

Image 7 | A control center for science: an infinite amount of measurement and sensor data is processed in the system control room at the Helmholtz Zentrum Berlin. The large-screen technology used for this is controlled via the KVM system MultiConsoling® from JST. Clear information processing and visualisation are elementary at the HZB. The video wall serves as a “single point of control” for the entire team.

Image 8 | Maximum availability: A total of four large screens are available to the operator team in the central measuring control room at InfraLeuna GmbH for visualising the operating data. Seamless monitoring, early fault detection and efficient process control are of the utmost importance to the company. As the operator of the infrastructure facilities at the Leuna chemical site, one of the main tasks is to supply and dispose of water and to supply energy to the local industry.

Image 9 | Large-screen visualisation, KVM technology and ergonomic control room furniture are among the equipment elements that Jungmann Systemtechnik has implemented in the measuring control room for the chemical plants at INEOS Oxide in Cologne. With the PixelDetection® software, process surveillance is supported by a smart and proactive alarm system.

Image 10 | Integration of virtual machines, convenient mouse hopping from the workstation monitor to the video wall, intuitive control of the management system and processes in the facility as well as maximum security through full redundancy: The team in the control room of Nord-West Kavernengesellschaft mbH (NWKG) uses high-availability KVM technology from JST for the operation of the cavern system near Wilhelmshaven.

Image 11 | Mammoth project at PCK Raffinerie GmbH: A total of eleven satellite control rooms were merged into one central measuring control room in Schwedt, Brandenburg. In order to monitor and control the process chain efficiently, JST – Jungmann Systemtechnik® designed 25 operator stations for the plant staff. The equipment includes large-screen and KVM systems, software and a highly available backup concept.

How do others deal with the issue of automation in the measuring control room? Which new tools ensure optimised energy management in power plants, the integration of process control systems in the chemical industry or additional efficiency in the energy sector? How can seamless process monitoring and early fault detection be realised?

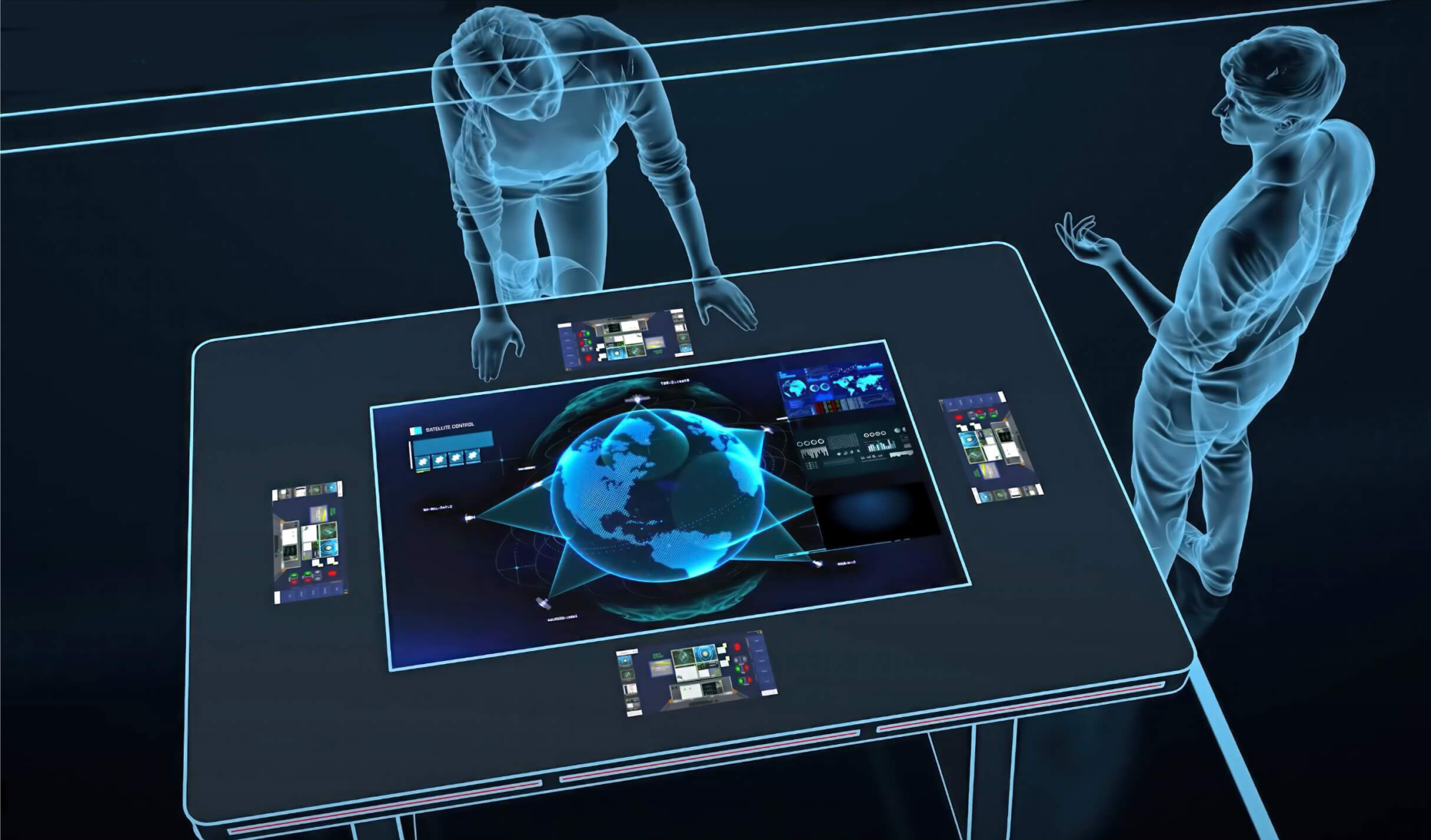

It is worth taking a look at reference projects that have already benefited from new components and intelligent operating systems and have thus been able to establish smart processes. Example: JST TacticTable®. Whether crisis scenarios or training – the interactive situation table with full integration into the control room management system creates the basis for efficient, team-based solutions.

Real-time monitoring of incoming data becomes the cornerstone of safe and efficient process control with scalable large-screen systems from JST. As the central display technology in the measuring control room, either monitor walls with LCD technology or innovative LED walls ensure maximum operational reliability and precise control of industrial processes and systems.

Critical parameters such as pressure, temperature and flow rate can be captured at a glance in a high-resolution, high-contrast visualisation. Whether faults, colour-coded alarms or status messages – relevant data is available to all operators at the same time on the video wall. Faults are recognised more quickly within the team. The response time is reduced.

We offer our customers unique products and solutions for control rooms. An exclusive benefit that only JST can provide.

We have been working in the business for more than 30 years. We would be happy to bring our many years of know-how to your project.

This means that you benefit from our extensive experience and smooth project realisation processes. Because JST keeps everything in mind!

Our experts are among the best. They have been designing control rooms for years. Our team enjoys working together – for you!

Clever solutions for the safe management of control room processes

Network-based KVM technology: smart and secure with JST MultiStreaming®

Efficiency, productivity, security – that’s what JST MultiStreaming® stands for. Connect all sources conveniently and flexibly via the network using IP streaming. Even remote access to worldwide target locations is possible – stable, in great quality!

Video wall, workstation and infrastructure under control with the myGUI® platform

The intuitive myGUI® user interface in the 3D layout of your control room offers maximum ease of use for controlling your systems. With just one click you can operate workstations, infrastructure, LCD and LED walls – reliably, even in stressful situations!

MultiConsoling® – the high-availability command center for your control room

MultiConsoling® is the high-availability control center for connecting all signals from your systems to the monitors at the user’s workstation and to the LCD and LED walls. Transmission takes place in real time and does not require any software on your computers.

Experience more at a planning workshop in the control room simulator

Having visions of the future is good. Experiencing is better! Visit the control room simulator, unique in Europe, where state-of-the-art technology and the latest ergonomic know-how are combined. The control room of the future. The special feature: Here you can touch everything and try it out for yourself.

Whether virtual or live on site – the workshop in the control room simulator is free of charge.

We kindly ask for prior registration.

What customers say about their experiences with measuring control rooms from JST – Jungmann Systemtechnik®

„The colleagues are impressed by the progress we’ve made here.“

„High flexibility, reliable performance, no more annoying chair moving – that was already a great experience!“

„The whole package was really coherent, and we also really liked the dedication of the Jungmann employees.“

This is where visions become reality: JST components pave the way into the digital age

The integrated control room models from Jungmann Systemtechnik set new standards in efficiency and resource management. Innovative components make the control of your company’s strategic and operational core tasks not only more convenient, but also more secure. We are at your side to develop an overall concept for you that meets the requirements of an increasingly automated world.

The smart multifunctional table sets new standards

Leading furniture designers have created the AllMedia exclusively for JST. The conference table is far superior to conventional models. The reason: Via JST MultiStreaming®, the system connects the conference room directly to the sources of the control center, which are immediately available.

The right video wall for every room

Monitor walls from Jungmann Systemtechnik adapt exactly to the structural requirements and size of your control room. We offer various options for different needs, ranging from the carrier plate for wall mounting the monitors to mobile DisplayRacks and multifunctional DisplayWalls.

Increased attention in case of events

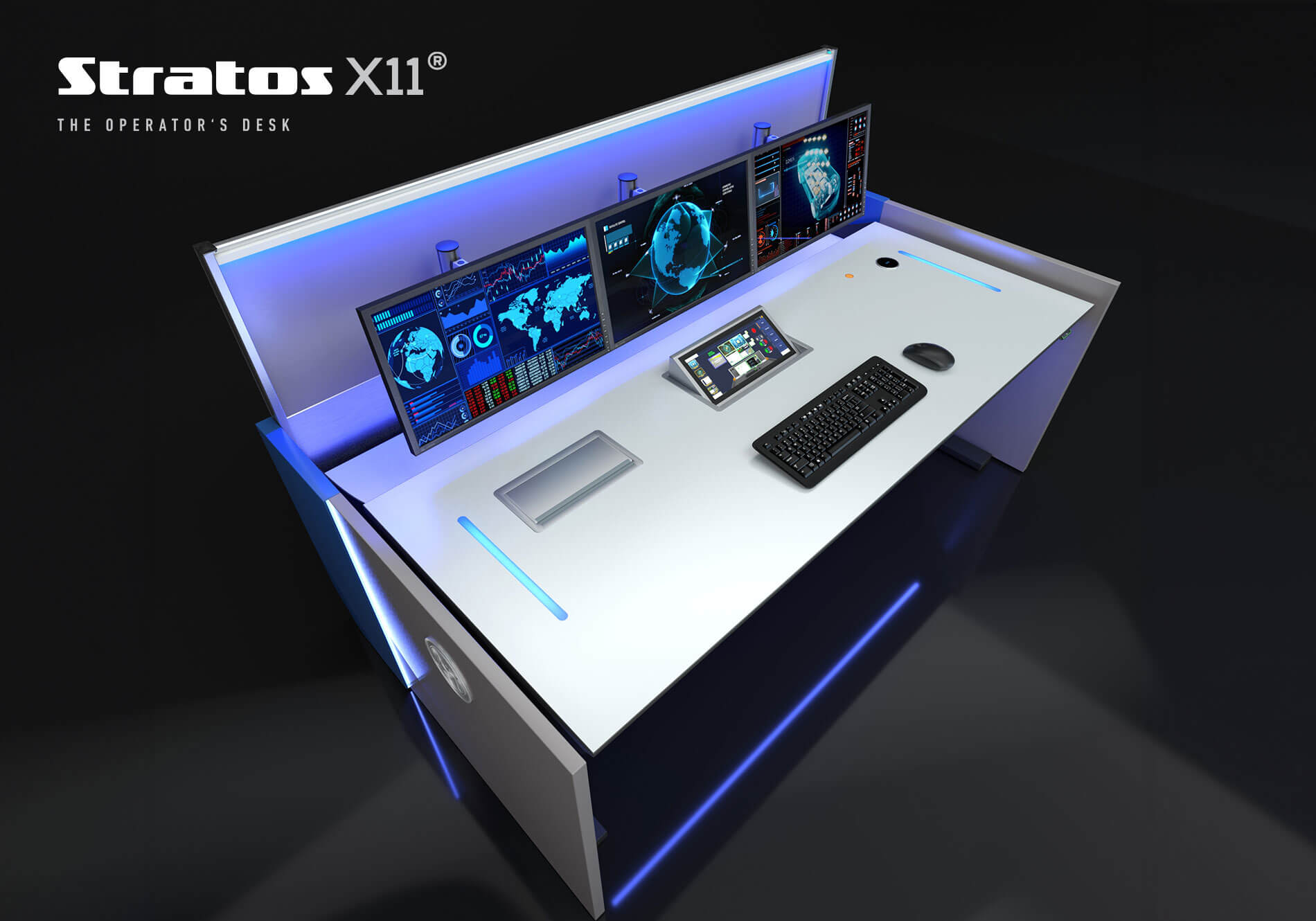

Whether DisplaySuit, Stratos X11® operator console or OPAL X11® ceiling sails – the integrated AlarmLight changes color depending on the event and thus attracts everyone’s attention. Red or pulsating light gives the control room team a clear signal: “Attention! A reaction is required here!”

JST DisplayWalls – the team players in the control center

Video walls from JST are the basis for a new level of event-oriented surveillance efficiency. Crystal-clear 24/7 displays and the integration of of real-time data pave the way for precise monitoring and fast decision-making. Proactive alarm visualization reduces response times.

Security and convenience go hand in hand

Access-protected and air-conditioned, the control room hardware is housed in the external technology room via extender solutions. Data is transmitted in real time without any loss of quality. An additional benefit: heat and noise pollution are kept away from the control room.

Masterpieces in the control room

Fully integrated operator consoles “made in Germany” impress with their workmanship, design and fulfillment of legal ergonomic requirements. By merging with the hardware and software solutions developed by JST, the Stratos X11® becomes an indispensable command center in the control room.

Interactive, creative, communicative!

A multifunctional situation table as a central hub. The JST TacticTable® is gaining a foothold in the market as a smart information hub for all control room applications. The performance potential and skills of the individual are multiplied by bundling creative concepts and ideas in a team.

IP streaming solution for control room management

Operate any source on any desired screen. Just one mouse and keyboard required for all applications. Intuitive handling with the myGUI® interface. Cost-saving and with a sharpened focus on security. The convenient KVM solution JST MultiStreaming® offers flexibility without limits!

Fixed contact person for all phases of the project

Workflow and task coordination with the specialist departments

Professional implementation of all components

Employee training and initialization of the new Control Center

Turnkey Solutions:

Integrated overall solution creates a real competitive advantage

You want a control center where all information comes together? A control room as a secure basis for the requirements of the digital future, precisely tailored to your processes and needs?

With our experience from more than 600 projects, we are the right partner for turnkey solutions that transform your control room into a profit center.

The right solution for each process control center

Ergonomic furniture, video walls, control technology and much more – the JST world offers the entire spectrum of control room equipment. Whether warehouse control station, operations center for logistics or intralogistics: Wherever material flows need to be controlled efficiently, wherever inventory handling and warehouse management are involved, JST supplies suitable and customised concepts. Watch our videos to find out how comprehensive our support is and what modern options for alarm detection with JST look like.